RAILWAY / AUTOMOTIVE / AERONAUTICS / MARITIME INDUSTRY

We offer a global vision of the systems, components and elements that are integrated in a transport element:

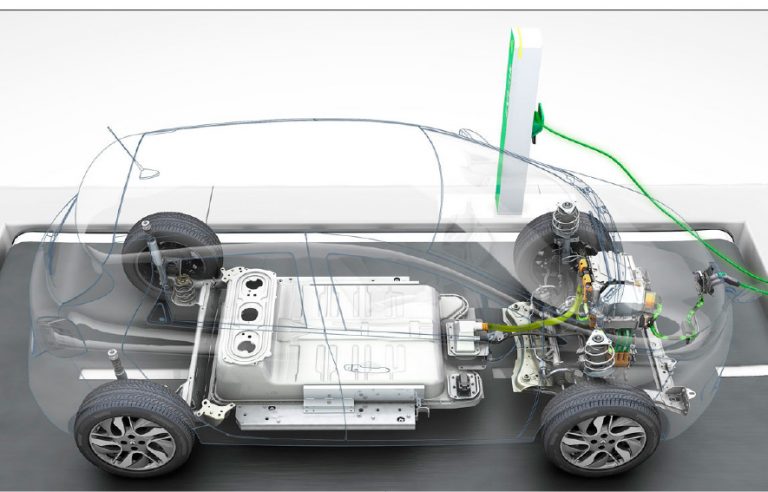

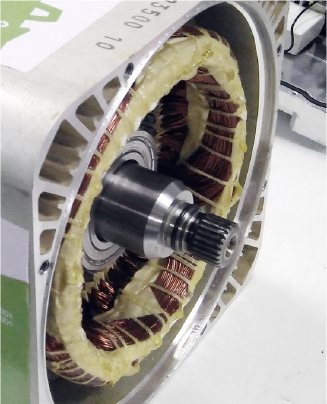

- Constructive characteristics, operation and regulations of the most current engines, diesel, gasoline and electric.

- Chassis; design, construction characteristics, passive safety and materials that are currently being used in their manufacture.

- Characteristics of all systems and components involved in vehicle dynamics. Transmission systems, suspension, steering, brakes and active safety systems.

A vision that helps us to understand how the design and the way each component is manufactured influences the rest of the systems. This helps us to identify the critical components and elements that are directly involved in the dynamics, safety and reliability of the whole system. In this way, we can provide solutions and improvements, both in the design process and in the production process of components, assemblies and subassemblies.

We offer customized solutions, meeting the technical needs of each company. Both to companies in the component manufacturing sector, as well as to companies in the after-sales service sector (diagnosis, maintenance and repair of vehicles).

Also, our extensive experience in the use and implementation of environmental regulations, such as order and cleanliness, will provide you with a more objective point of view and even a safe platform to start working with these new methodologies.

The equipment we have in our centers.

- Lifting equipment, dynamometers

- Steering aligner

- Wheel balancer/tyre changer (passenger cars)

- Plasma cutting machines

- Paint laboratory

- Paint booths

- Welding booths (TIG, MIG, MAG, oxyacetylene and electrical)

- Strobe Lamp - PRE-2324

- Ecoboost direct injection engine

- BMW i3 electric power train (engine, transmission, power electronics)

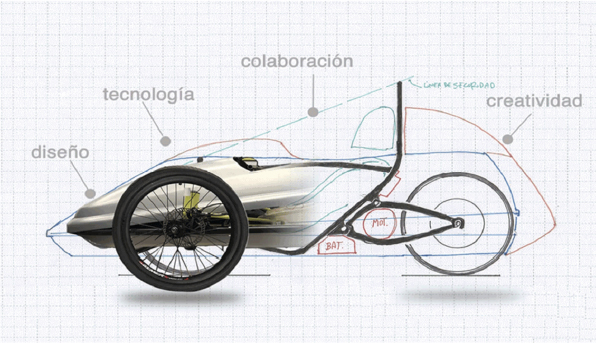

- Euskelec demo vehicles

- Toyota Prius hybrid vehicle trainer (loan of resources)

- Alecop ADA 307 hybrid and electric vehicle trainer

- Software for the simulation of sheet metal forming processes PAM-STAMP 2G