- Duration: 3 months

- Year: 2023

- Participants: Txorierri Politeknikoa + Muelles Federtek S.L.

- Industry 4.0 and advanced manufacturing

Project description

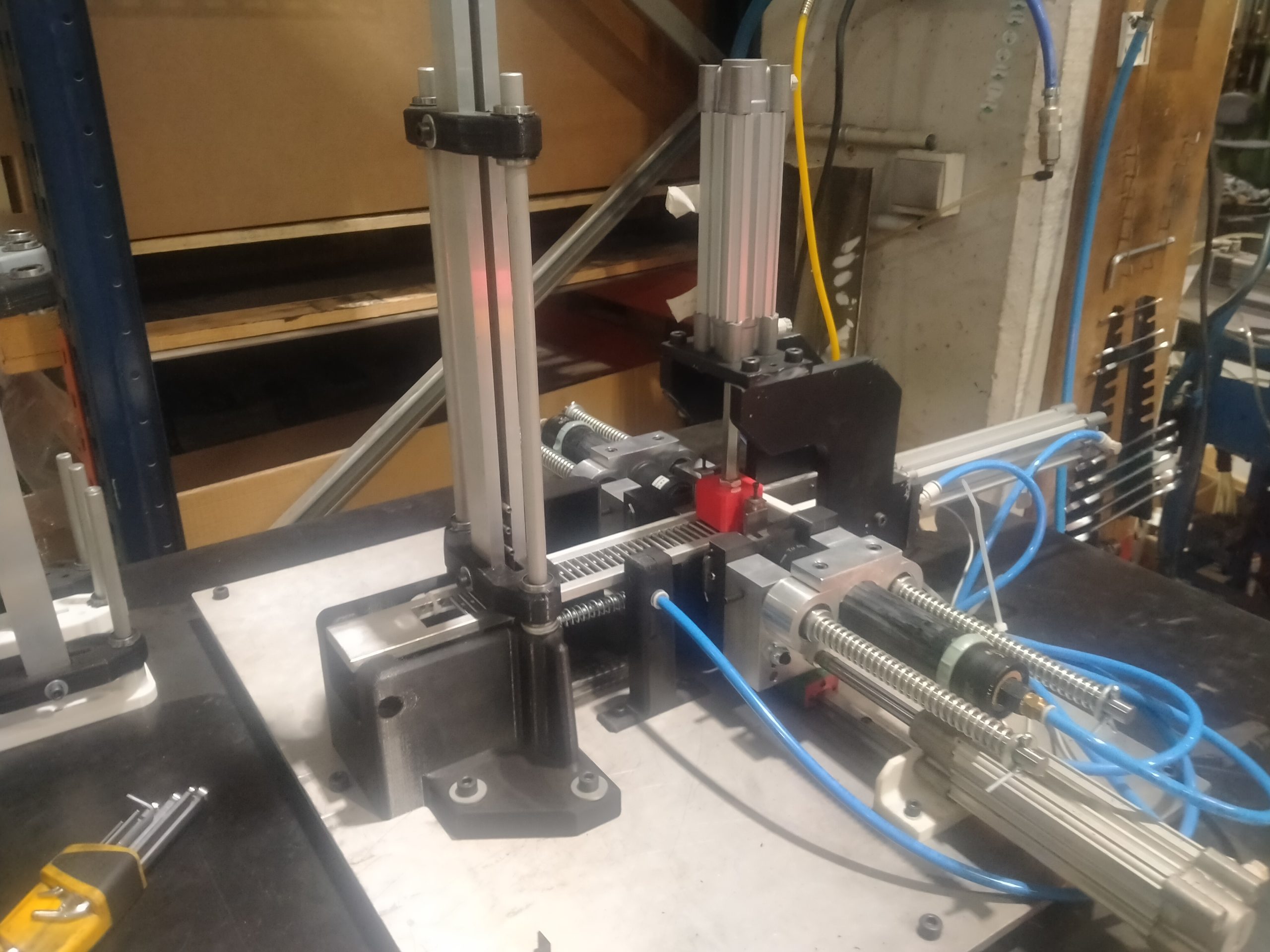

At the request of Muelles Federtek S.L, the execution of a turnkey system for the automation of a process of picking up parts and feeding a welding machine using collaborative robotics has been completed.

In the process studied, the operator collected the manufactured parts from one machine and placed them in another welding machine with a minimum opening so that these parts were welded. Once welded, he placed them in a box for storage.

With the automation enhancement installed, not only are times reduced, but the process has also been standardized, increasing repeatability and consistency.

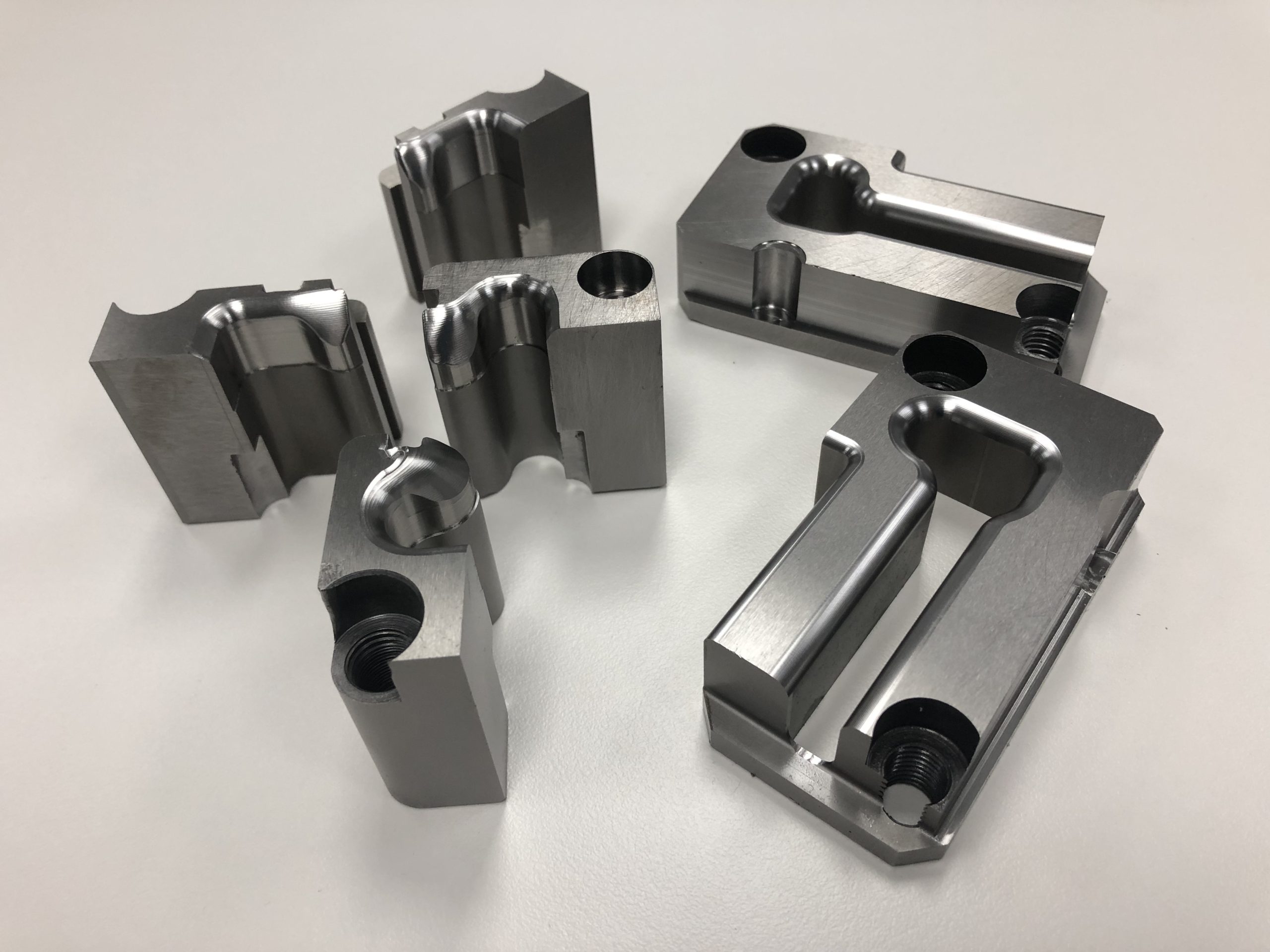

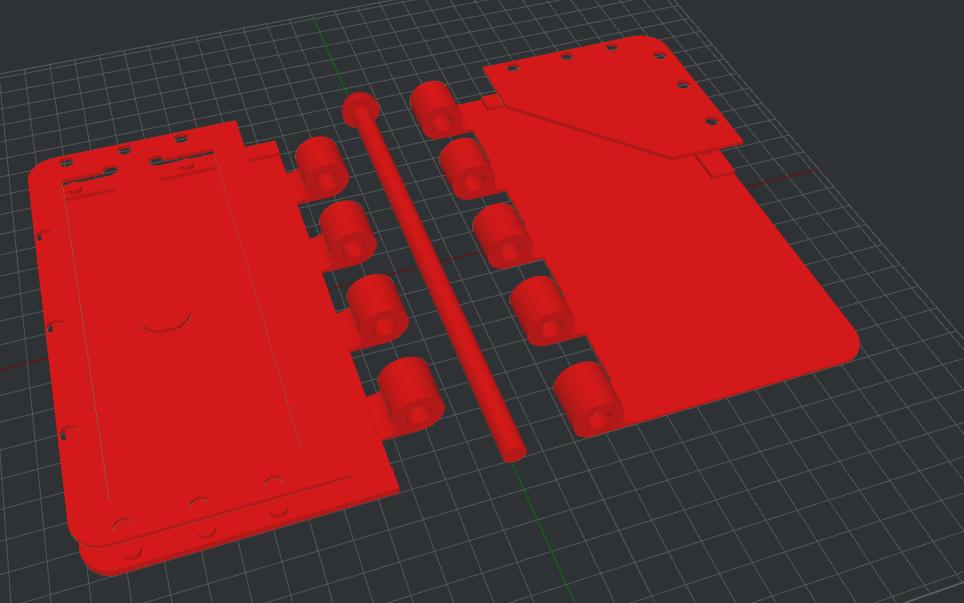

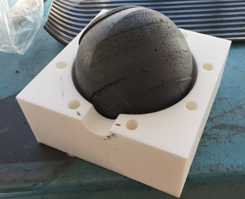

The solution has involved the automation of the process described above based on a collaborative robot (COBOT) and a series of peripherals and automation elements such as a claw-shaped tool.

A series of quantitative improvements should be highlighted:

- Increased plant production capacity: the operator’s time is freed up to perform other functions.

- Improved production cost: the robot counts the parts and stops the process when the planned parts are reached, preventing extra parts from being produced.

We also obtain qualitative improvements

- Improves the repeatability of the processes of:

- Removal of parts from the initial production machine

- Placing and removing parts on the welding machine

- Improvement of Health and Safety conditions by eliminating monotonous mechanical tasks for the operator.

Tasks Performed

- Study of the process to be automated

- Design of a gripper using the Catia V5 program

- Printing the gripper using Ultimaker printer

- Programming the UR 5 collaborative robot

- Commissioning of the complex