- Duration: 200 hours

- Year: 2023

- Participants: CIFP Bidasoa LHII + CIFP Don Bosco LHII + Egaña Caucho S.L.

- Industry 4.0 and advanced manufacturing

Project description

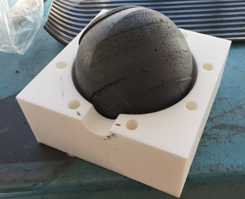

In the manufacturing process of SILENTBLOCK shock absorbers, which Egaña caucho S.L. produces, that is to say, in the transfer moulding process, threaded pins are placed to prevent the introduction of rubber into the metal sheet. In the past, the workers extracted them by hand, but today this work is done automatically.

In a previous project, a prototype of a large diameter SILENTBLOCK dowel extraction machine was implemented and if the dowels were on both sides, first the dowels on one side had to be removed and then the dowels on the other side.

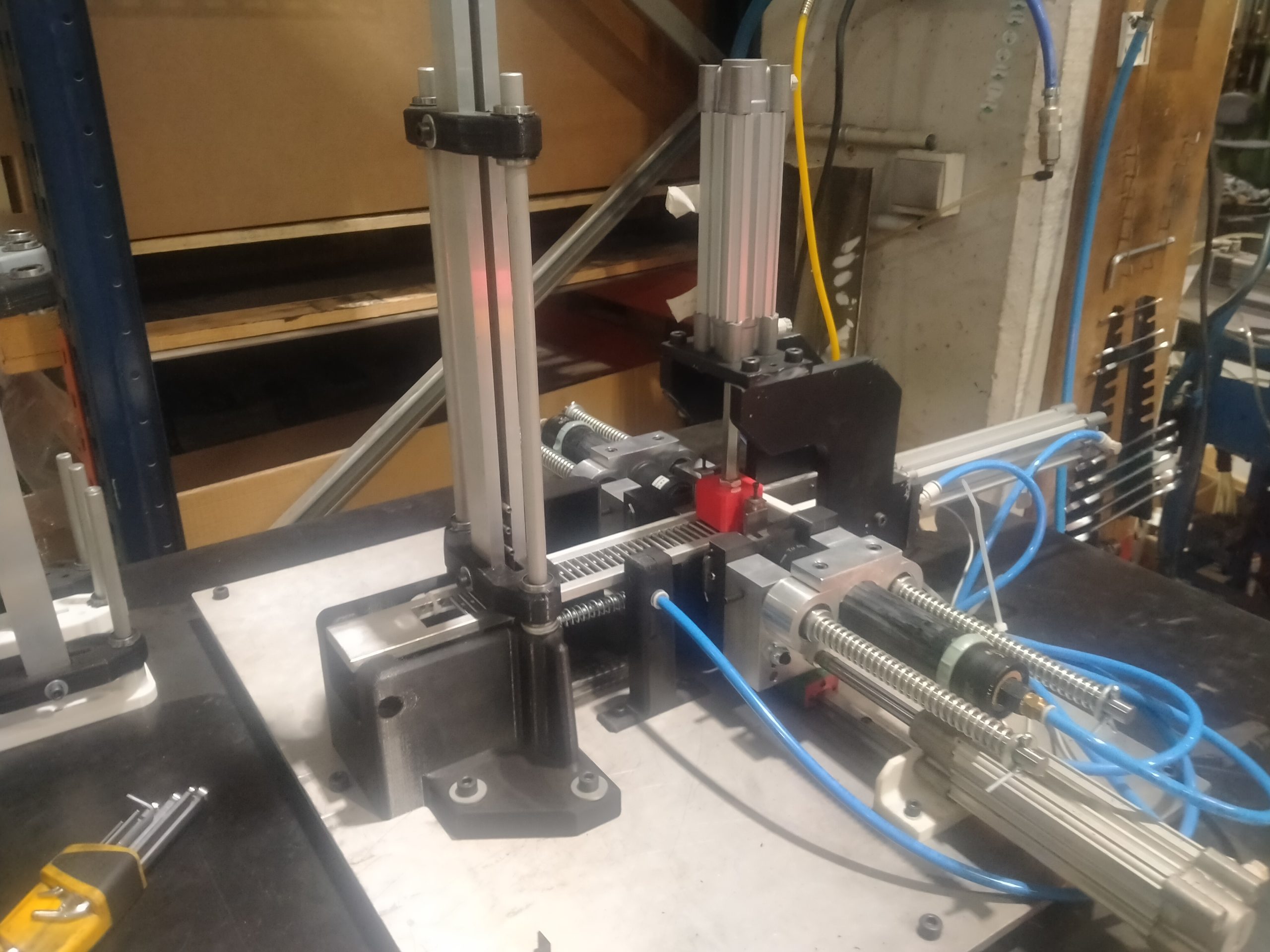

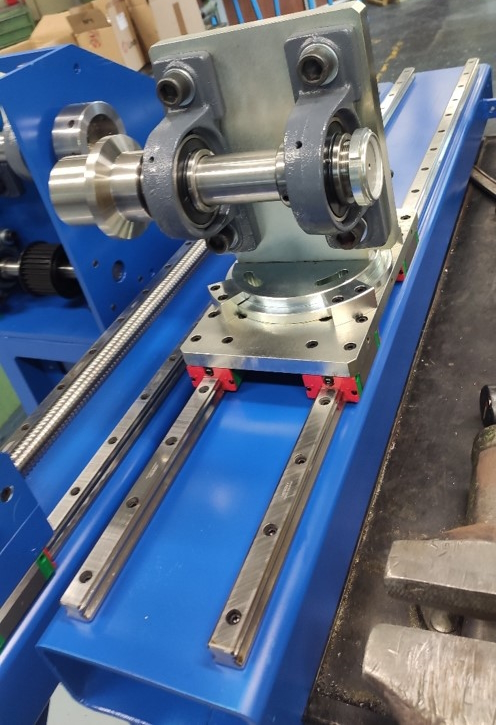

In this project, a system has been developed that allows the joint extraction of the two threaded nipples used in the manufacturing process in the SILENTBLOCK shock absorbers, with the collaboration of the company Egaña Caucho S.L and the centers: CIFP Don Bosco LHII, in which the design proposal and automation of the machine were made. and CIFP Bidasoa LHII, in which the parts were manufactured and the final assembly was carried out.

Tasks performed

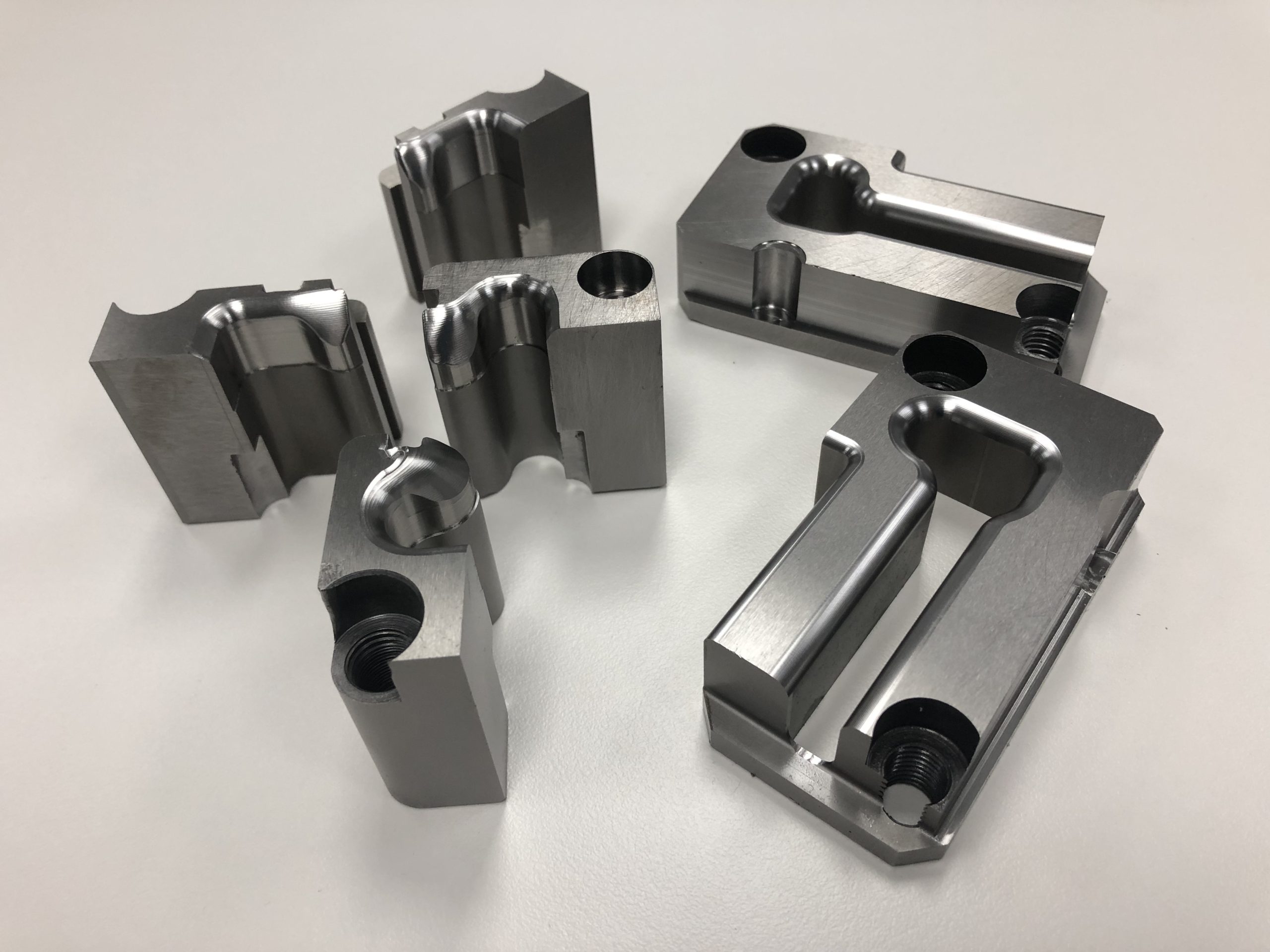

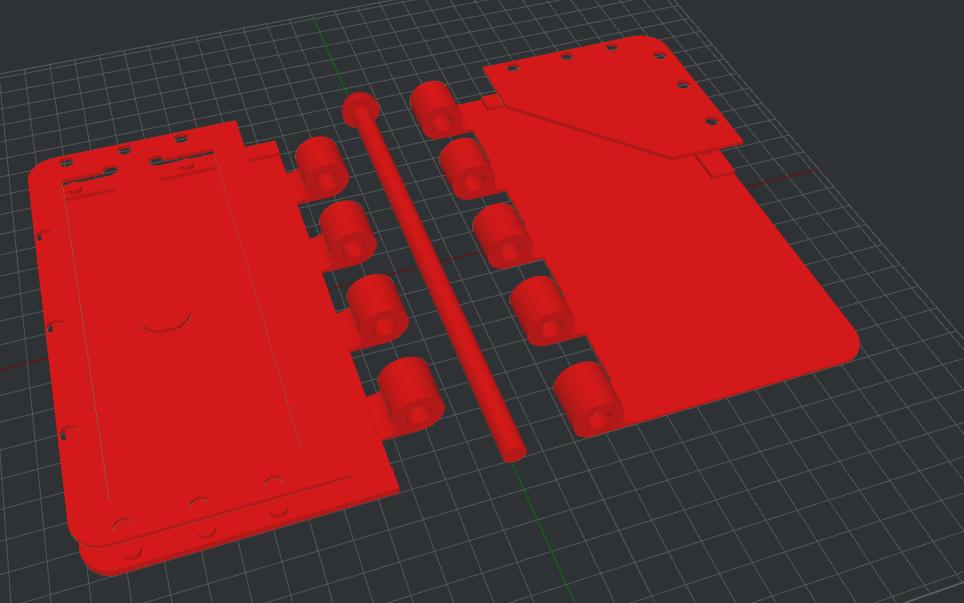

- To improve/optimize the design using 3D CAD based on the study of the production system and the idea developed by Don Bosco in SolidWorks.

- Prepare the drawings for machining and producing the parts by additive manufacturing.

- Perform the necessary pneumatic assembly and programming of PLC automata.

- To implement the joint system and solve the problems that have arisen.

- Prepare the documentation generated in the project.

Link