- Durationn: 6 hours

- Year: 2023

- Participants: EGIBIDE y Cofradia Nuestra Señora la Virgen Blanca

- Industry 4.0 and advanced manufacturing

Project description

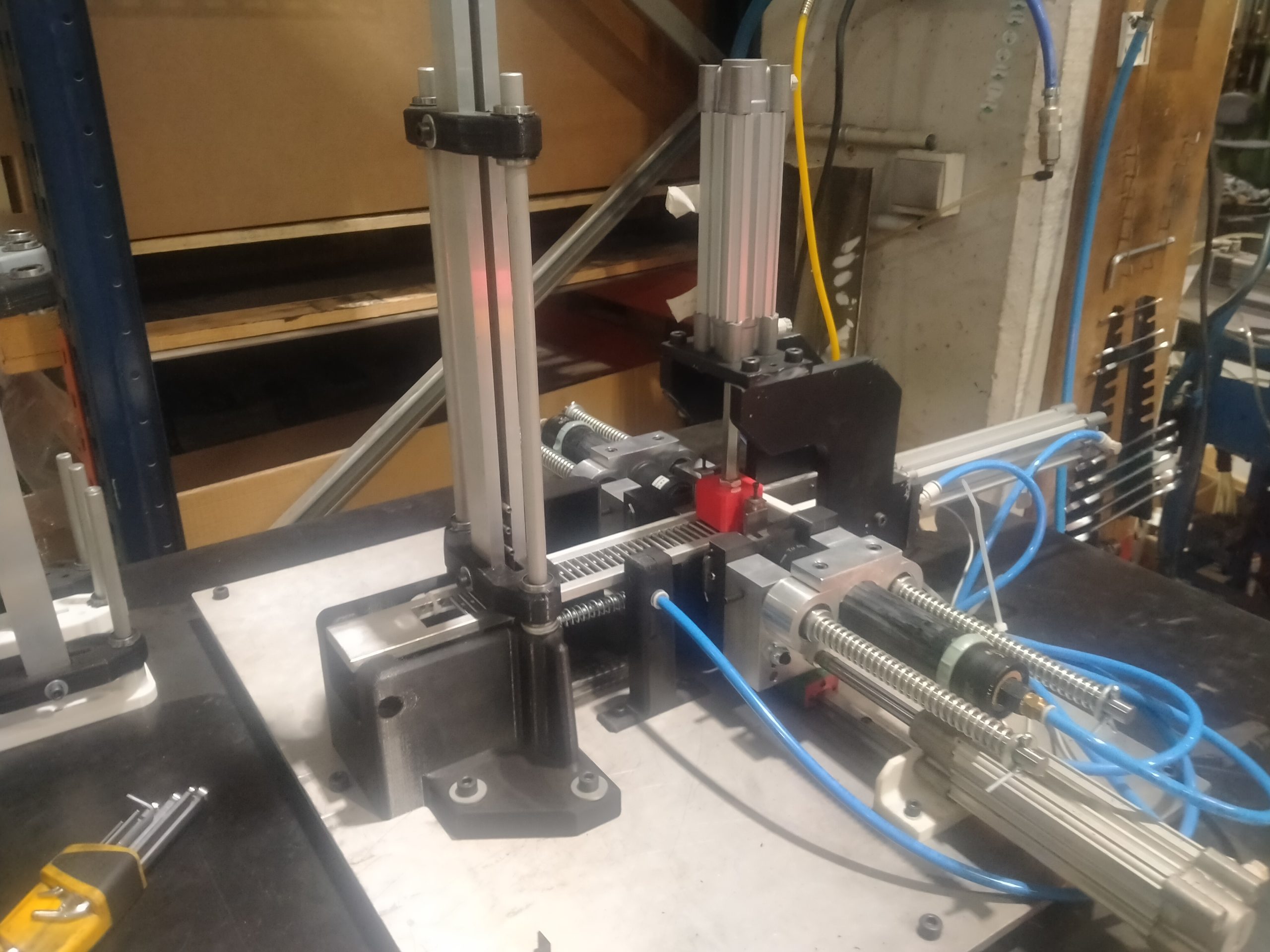

The Brotherhood asked us to design and develop a tool that would facilitate the placement of their lampposts and at the same time ensure a perfect fastening.

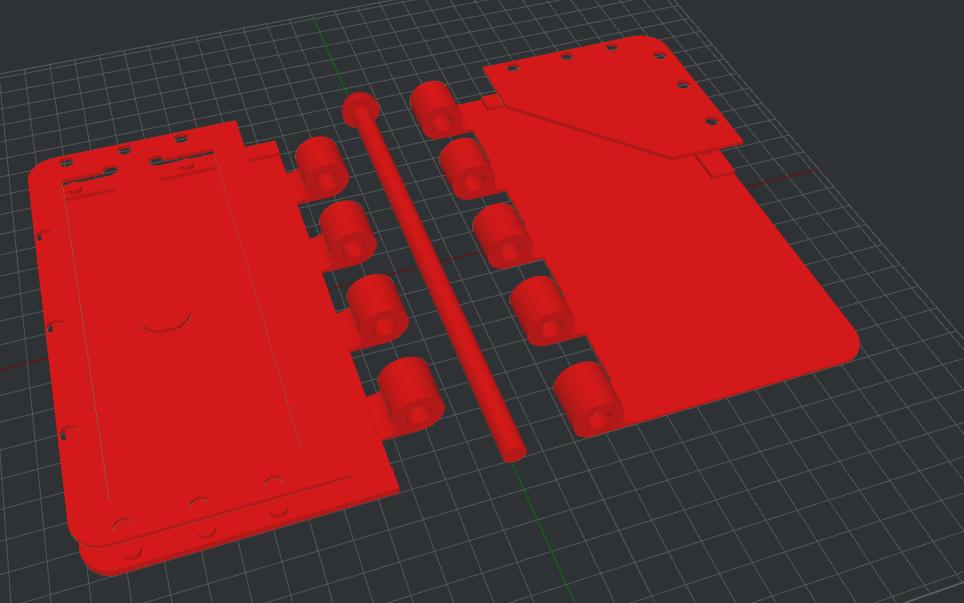

The development of the project was based on a first phase of prototyping different versions of a quick clipping system, which was presented to the company for analysis.

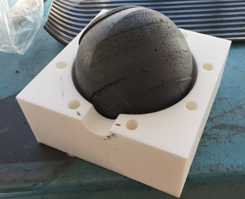

After the design was accepted, a study was carried out to assess the best way of manufacturing the different parts required. It was decided that the most suitable option was to manufacture them using additive printing.

Time was invested in assessing which was the most suitable material for the technical features required and it was seen that not all materials had the same response.

Once the material that met the requirements had been selected, the tools were manufactured using additive manufacturing.

The development went smoothly. We learnt techniques to improve production times, materials and additive printing.

Tasks Performed

- Analysis of the company's needs

- Design of the mechanical system using specific CAD software

- Prototyping and selection of the rapid clipping system

- Manufacture using additive printing