- Duration: 4 months

- Year: 2024

- Participants: CIFP IMH LHII + Bronymec

- Industry 4.0 and advanced manufacturing

Project description

As a result of the commercial campaign carried out by the IMH to explain to the companies of Elgoibar the aid for innovation by the City Council of Elgoibar, the opportunity arose to develop this project in BRONYMEC.

The company acquires a collaborative robot UR 10 with the aim of increasing productivity in a threading process linked to a large order from the company MITSUBISHI.

Thanks to collaborative robots, it is possible to:

- Perform part movements

- Feeding machines

- Assemble small parts

- Use tools for different operations

In short, not only do we manage to streamline production processes, but we also guarantee the precision of the operations carried out, as well as improving the quality of the workplace.

The project will consist of the design, manufacture and assembly of a tooling optimizing the load of the number of parts according to the maximum range of the UR 10, and its integration into the threading process of the MITSUBISHI part.

The resources we have needed have been the robot acquired by BRONYMEC, a threading machine to integrate it into the robot’s wrist and the knowledge of 3 teachers to be able to carry it out.

As a main result, we have learned how to design tooling, choose the right material, manufacture it and integrate all elements into a semi-automated process (parts are loaded and unloaded manually).

Tasks Performed

- Generation of the list of materials necessary for the tooling and purchase by BRONYMEC

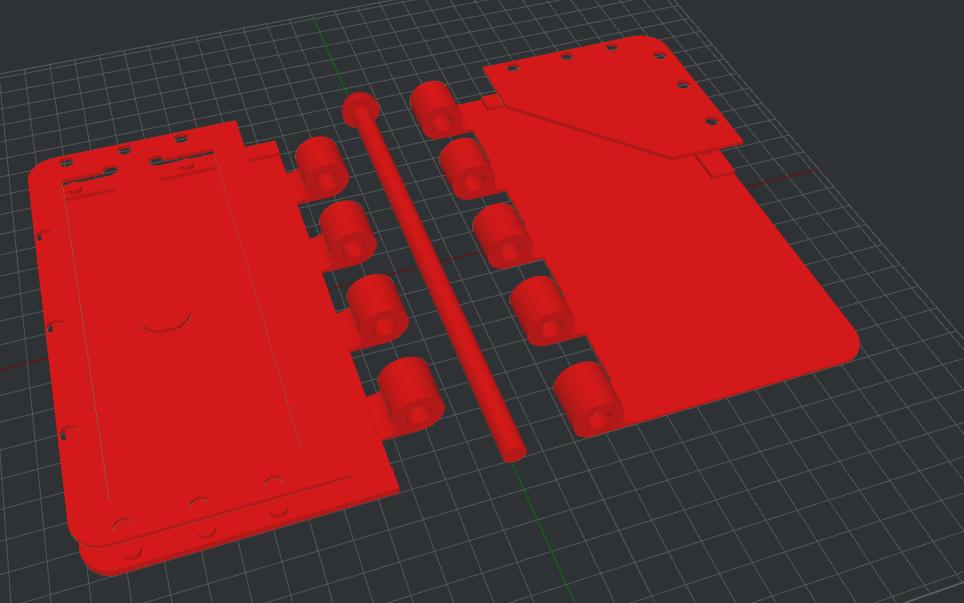

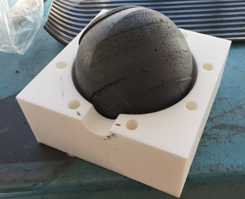

- Design and adaptation of the 3D solids of the part and the tooling

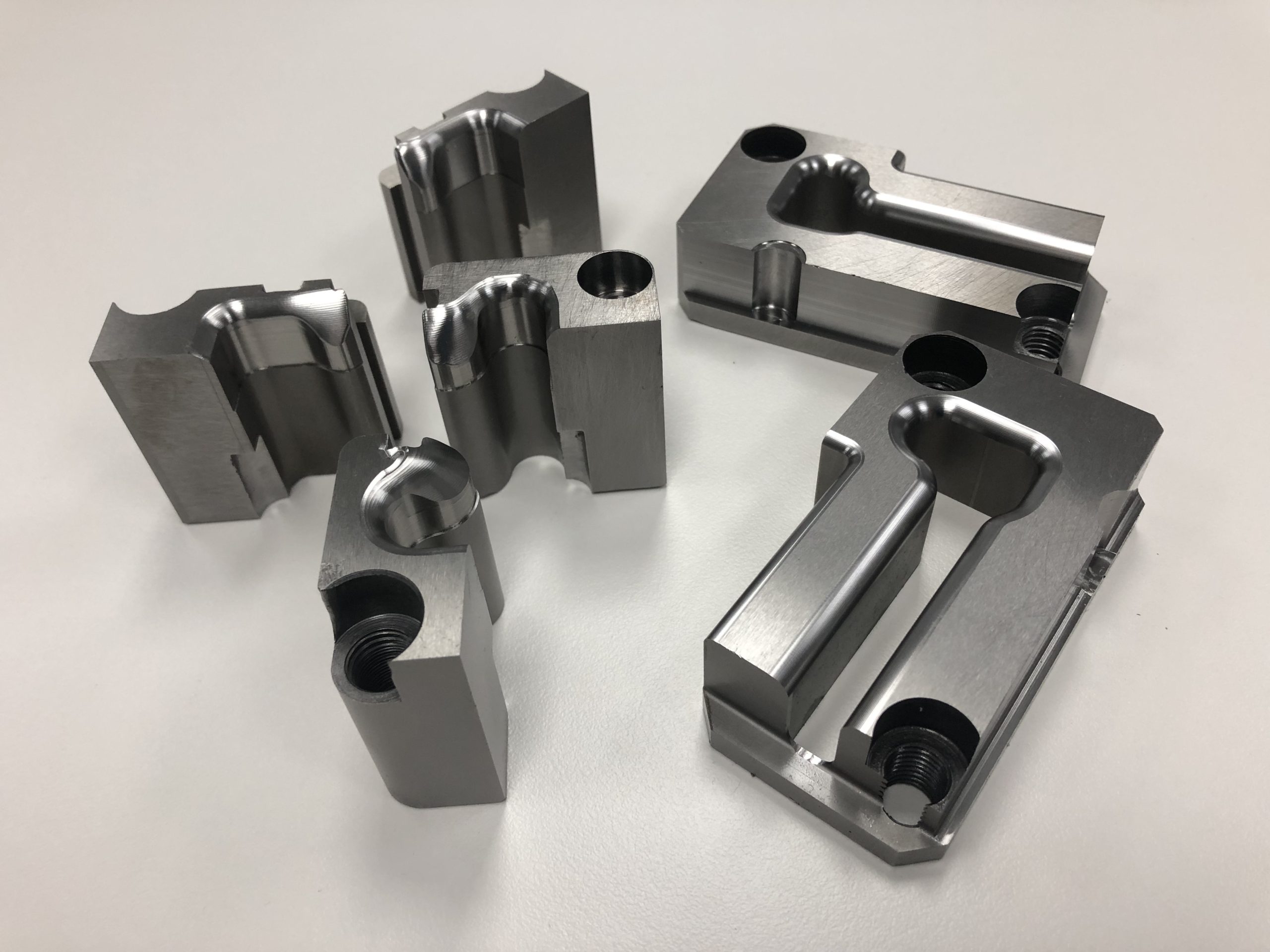

- Manufacture of non-commercial tooling components

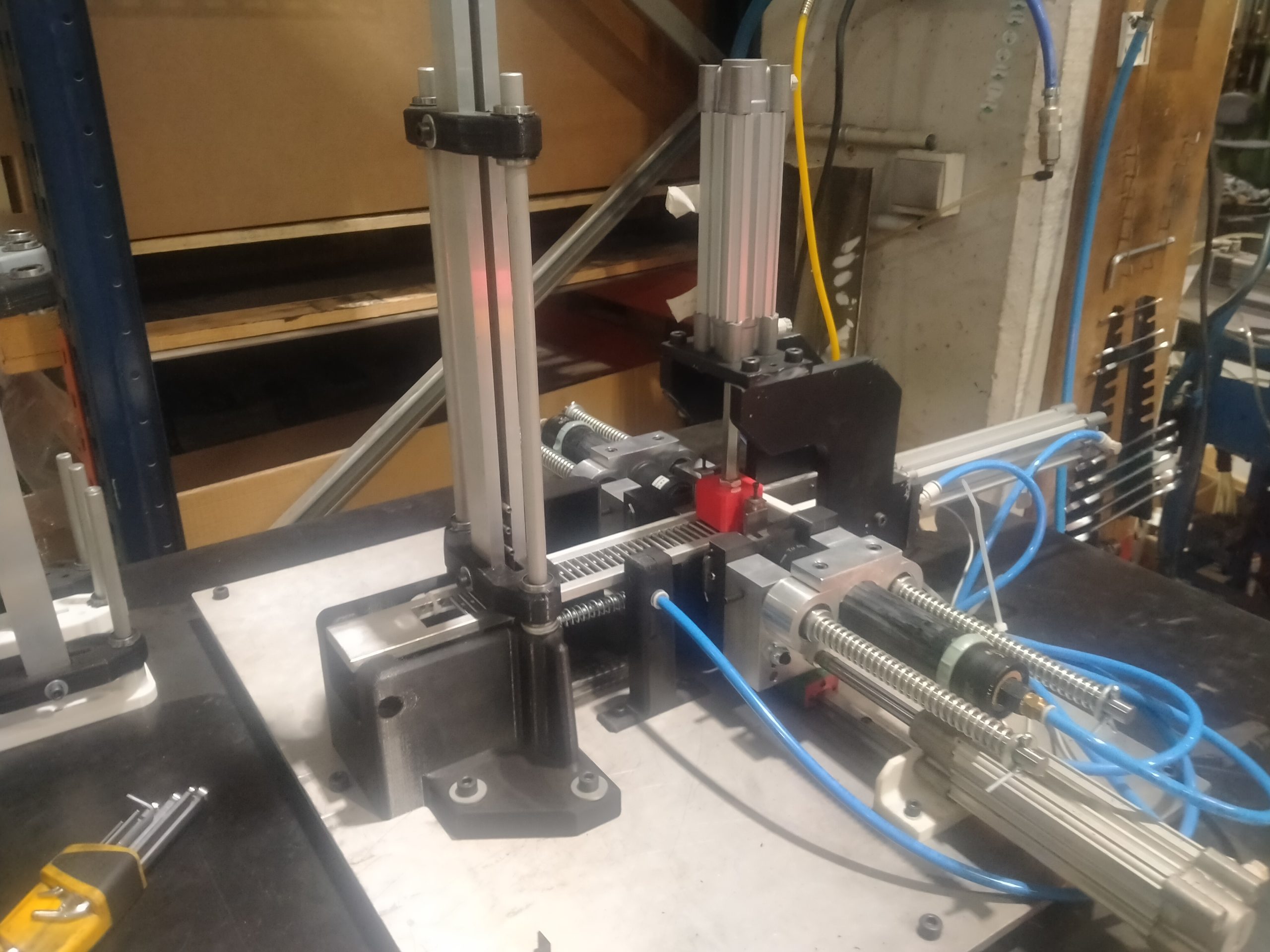

- Assembly and adaptation of the tooling

- UR 10 integration

- Experimental set-up and testing

- Customer validation