- Duration: 6 months

- Year: 2021

- Participants: IMH + BRONYMEC

- Industry 4.0 and advanced manufacturing

Project objectives

To respond to the need to use materials that develop lighter structures and comply with a series of regulations that regulate the response to the flame in the railway sector, BRONYMEC has designed a process of obtaining composite materials by infusing resin to a structure manufactured using additional technology for a specific set of parts in the sector.

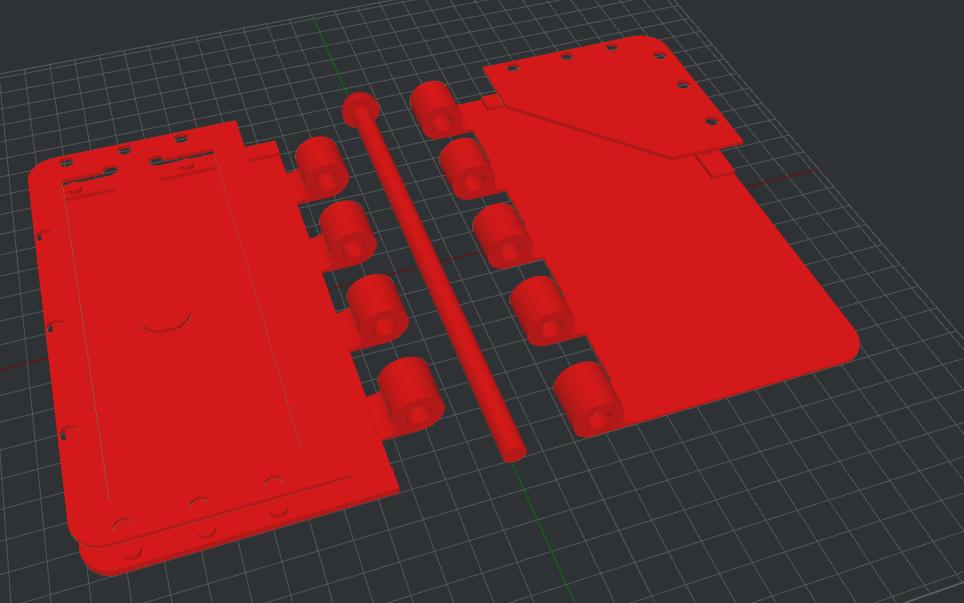

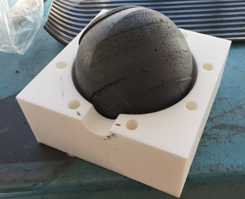

Within the framework of this project, and as a single-family piece, the IMH has designed and manufactured the basic structure of the piece and the outer shell, forming a mold in which the resin has been incorporated.

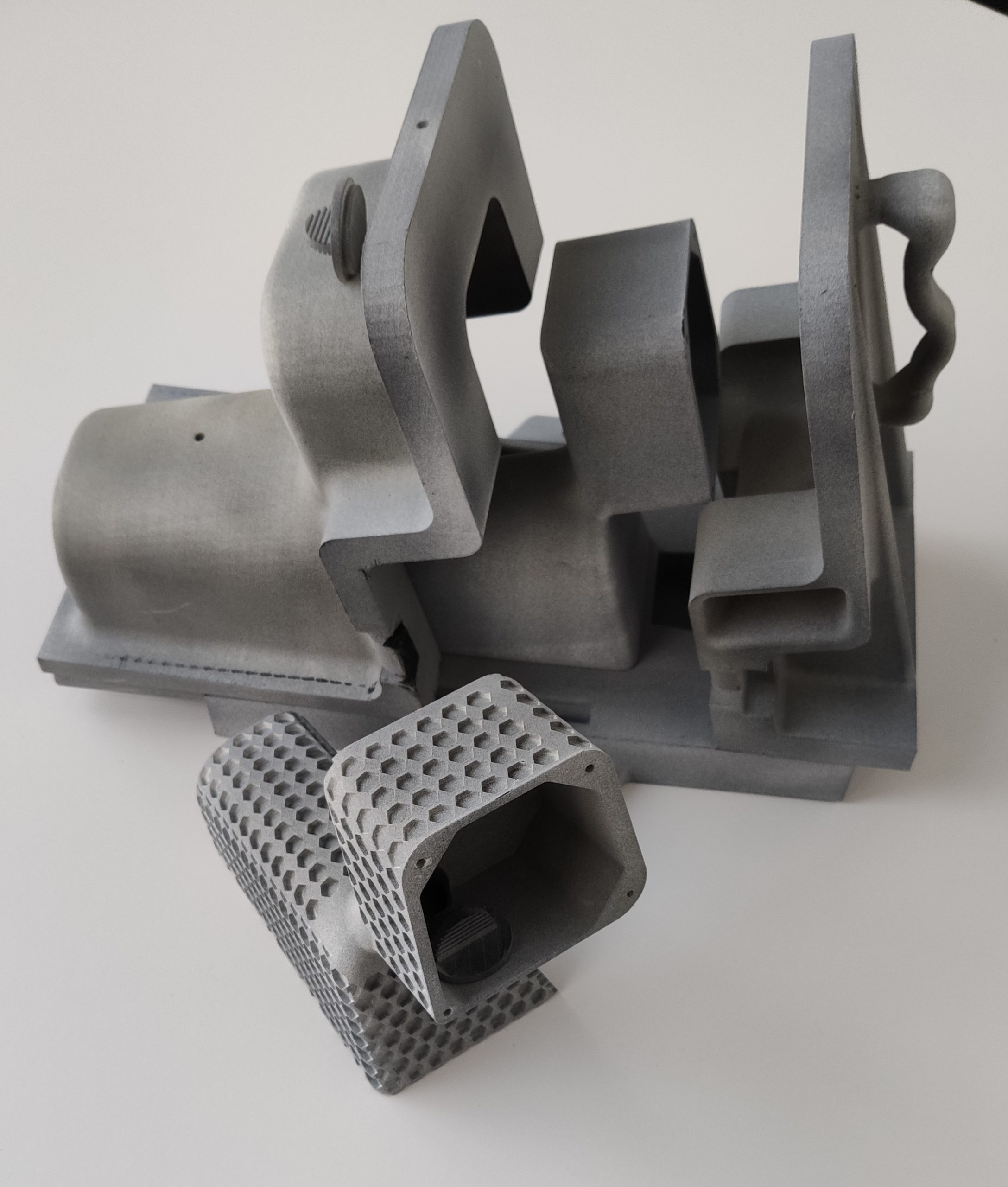

All this made with PA12 material in the HP4200 plant, with Multi Jet Fusion technology.

Tasks performed

- Design the new geometry of the piece adapting the additive process, applying mitigation techniques through lattice structures.

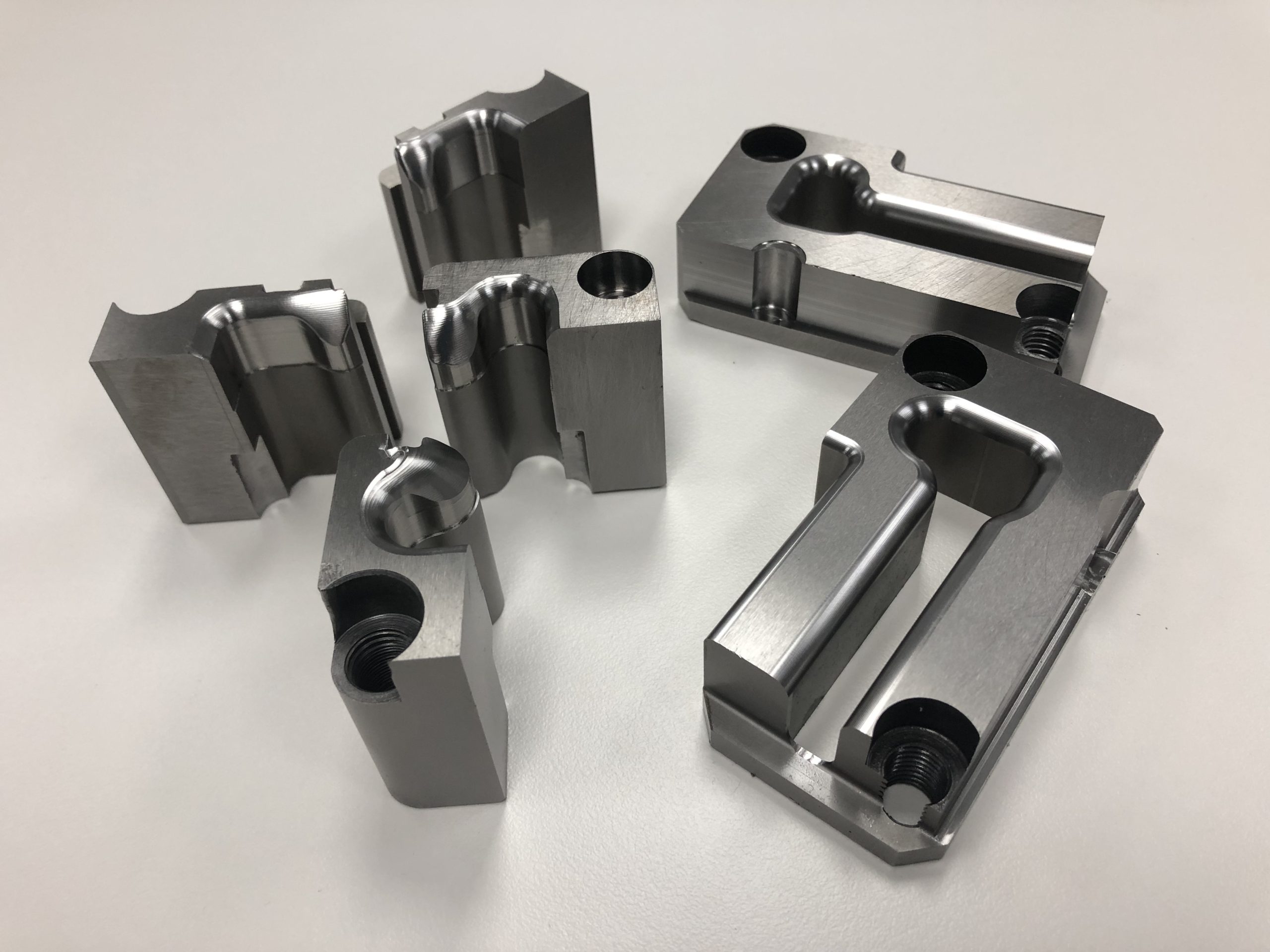

- Design of the outer side of the mold, maintaining a separation of the piece of 2 mm to coat resin.

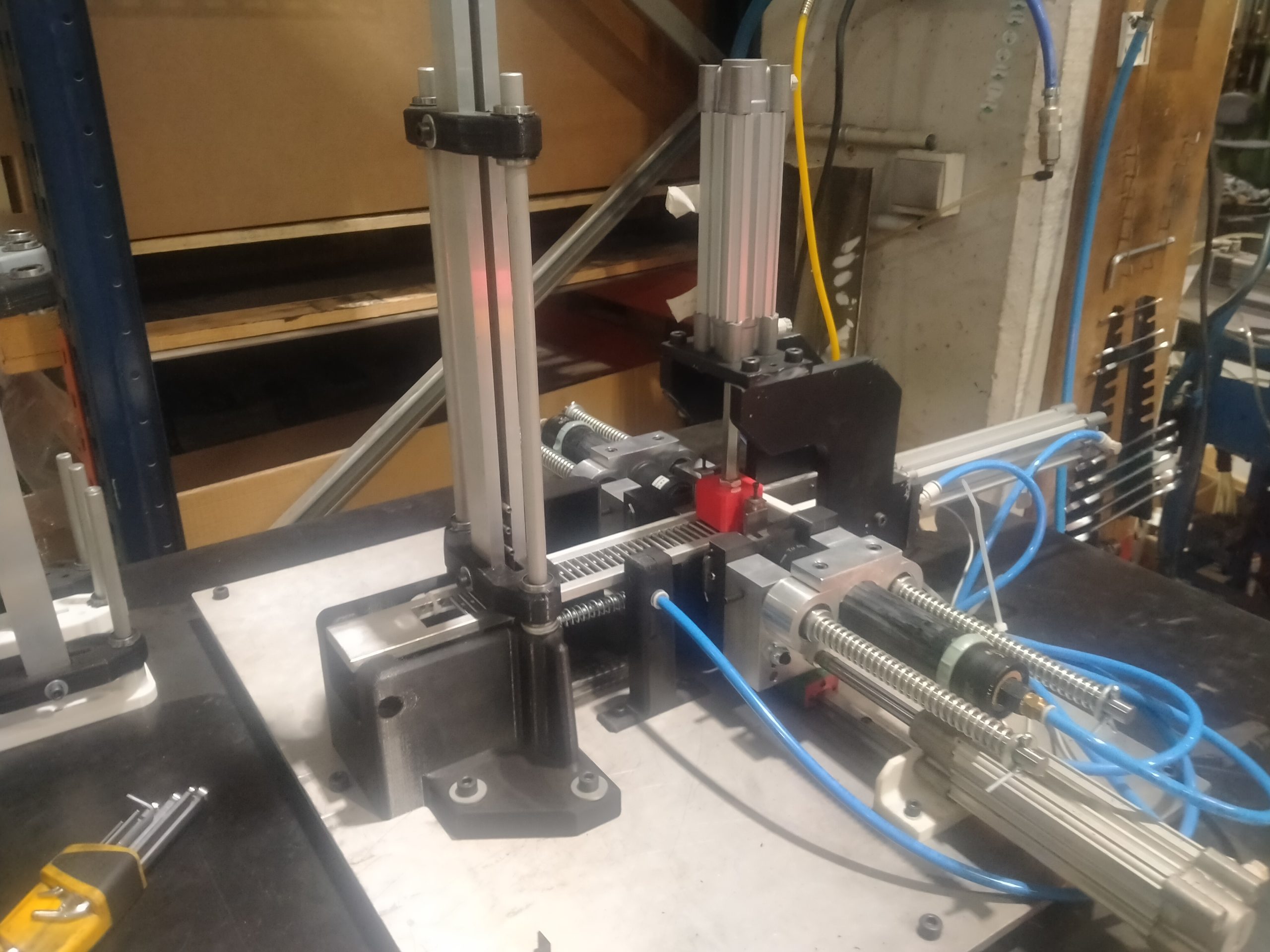

- Manufacture and assembly of parts for continuous injection.