- Duration: 12 hours

- Year: 2023

- Participants: Euskoiker fundazioko BISKY Team taldea + CIFP Iurreta LHII

- Industry 4.0 and advanced manufacturing

Project description

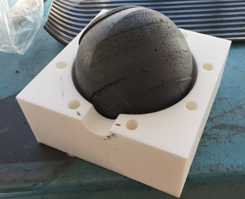

The BISKY Team, from the Euskoiker Foundation, wanted to test the new modular design of the rocket for the launch of the so-called ‘ATLAS’, thus facilitating assembly by means of individual modules.

In this sense, this project was born with the aim of responding to the difficulties of machining carbon fibre tubes.

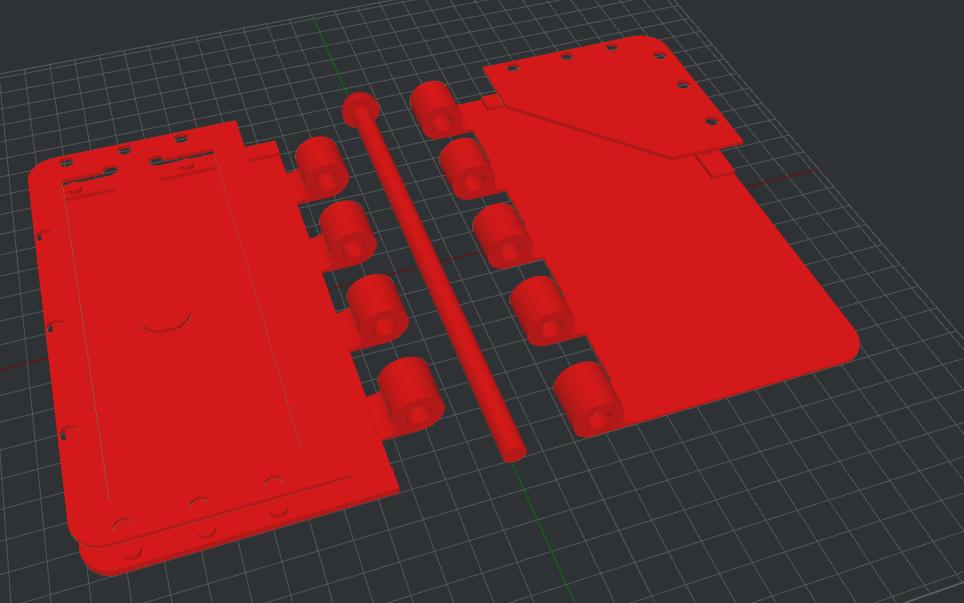

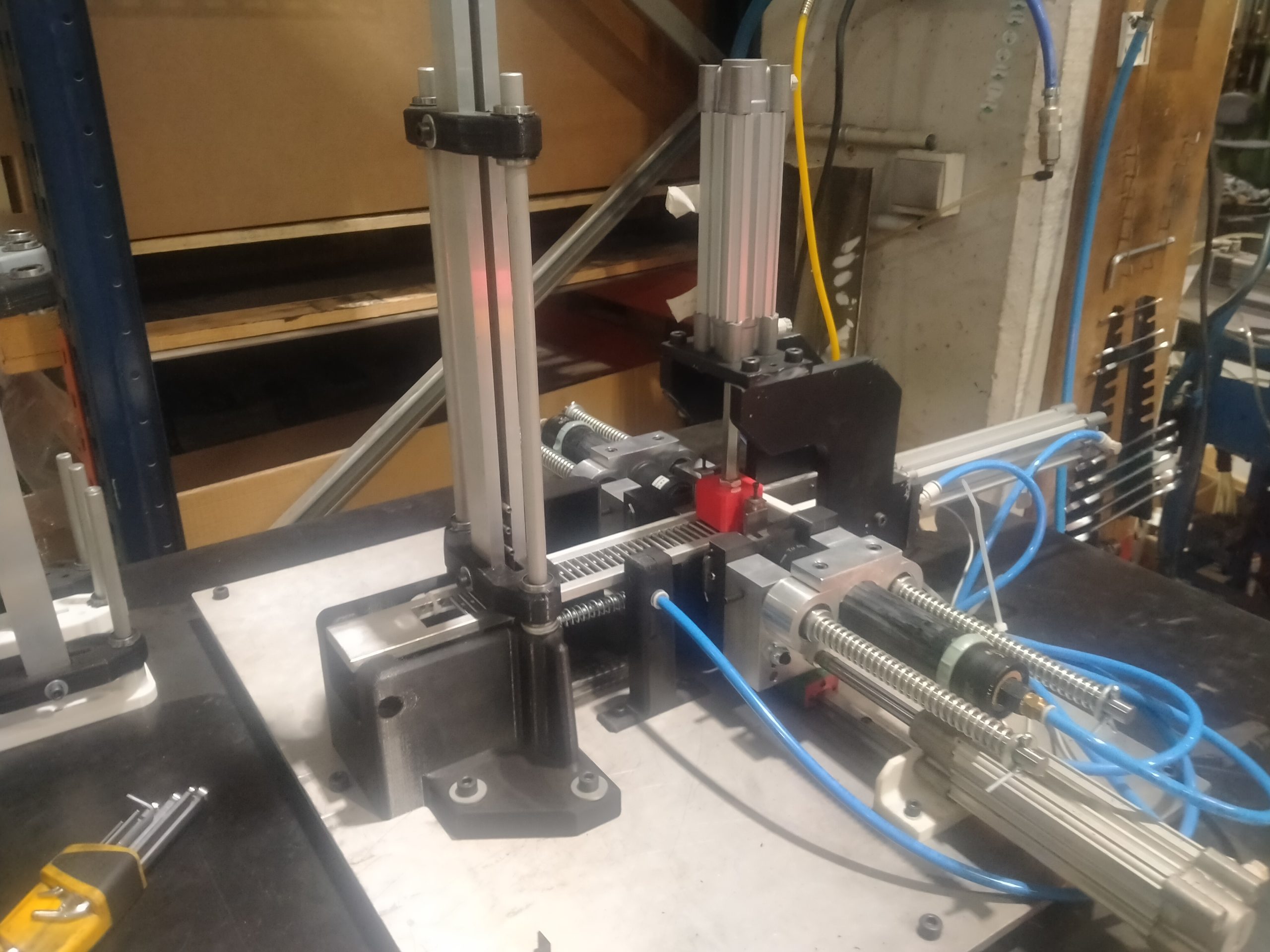

As the rocket contained thin tubes, when it came to machining it, it was necessary to think of a system to avoid deformation when tying it on the CNC machine.

The machine had to be set up for this task so that the fibre tube would be bundled on the 4-5 axis table and not deformed. In addition, when machining the carbon fibres, they expanded along the length of the tube and obtaining the required tolerances was a challenge.

Tasks Performed

- Meeting with Bisky Team and project consolidation

- Review of drawings

- Drawing up the CNC programme

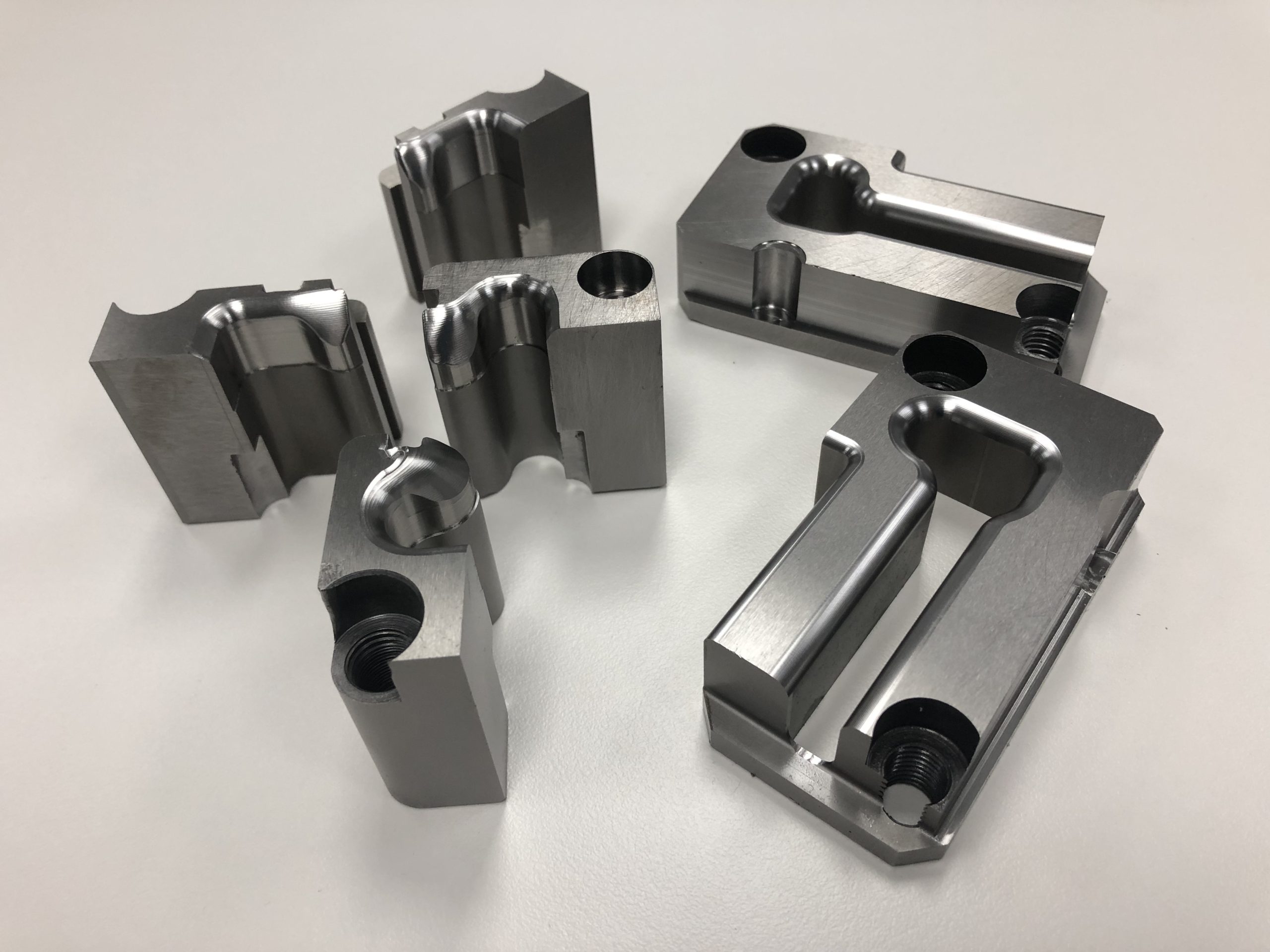

- Prepare machines, tooling and tools to be used

- Machining

- Assembly and preparation of the rocket

- Launching (carried out by Bisky Team)

- Analysis of results