- Duration: 41 hours

- Year: 2023

- Participants: INDAUX + Oteitza Eskola Politeknikoa

- Industry 4.0 and advanced manufacturing

Project description

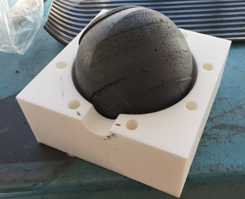

The 3D scanning of the parts provided by the client was carried out using the Kreon scanner. With this process, a .STL file was obtained for subsequent reverse engineering, setting the target in the .STEP file.

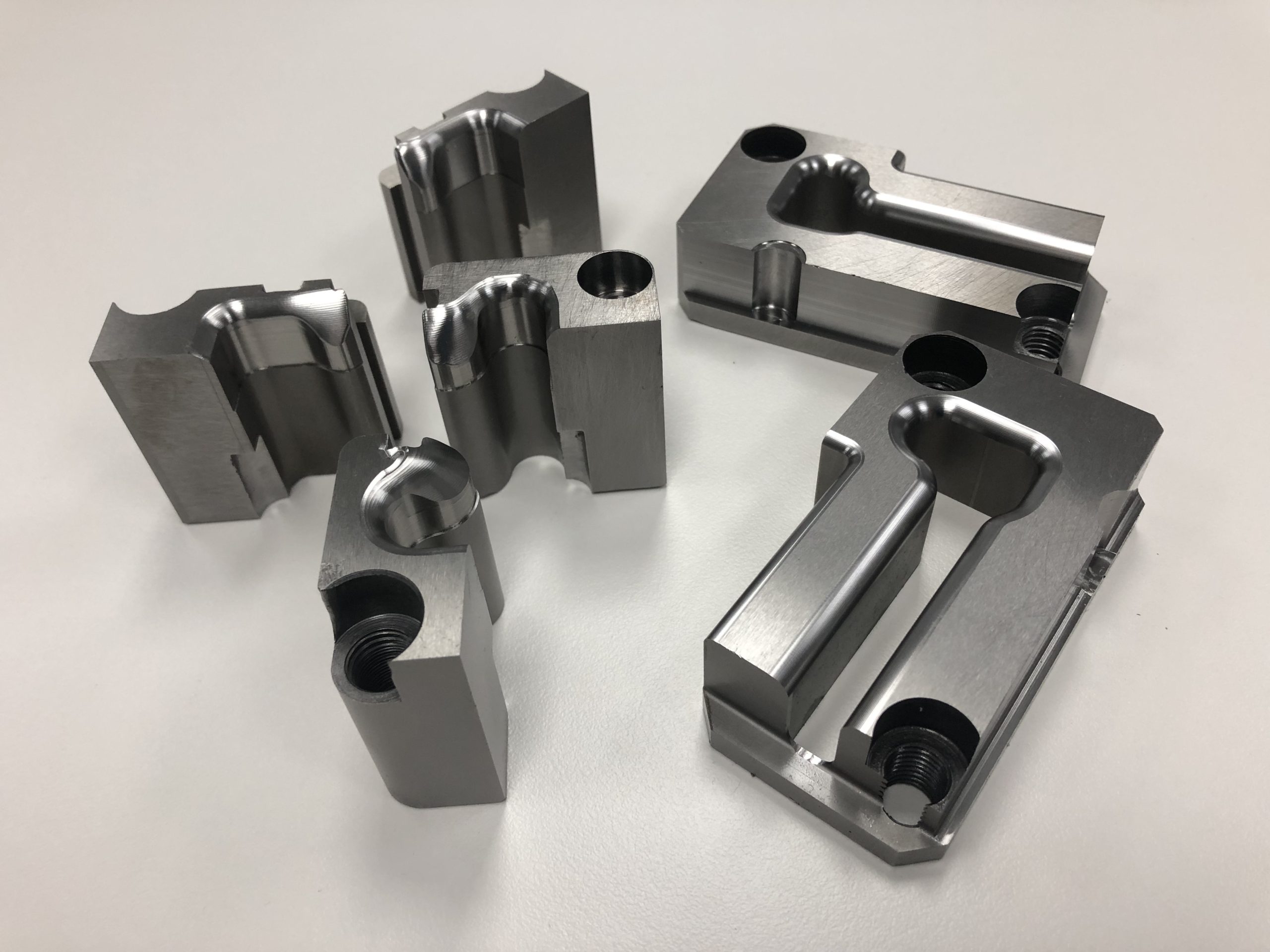

Subsequently, each part was developed in an NX CAM program. First of all, the machining strategies for the parts were defined, the selection of clamping/chucking to be used and then the parts were executed on the high-speed CNC machine model Kondia HS-1000.

For the machining of the parts, special tools have been used for the hardened material that allow us to respond to the hardness, geometry and characteristics of the parts.

The results of the work obtained were analysed and the parts were scanned after completion of the work, thus guaranteeing their conformity.

Tasks Performed

- Digitise the parts and obtain the .STL file

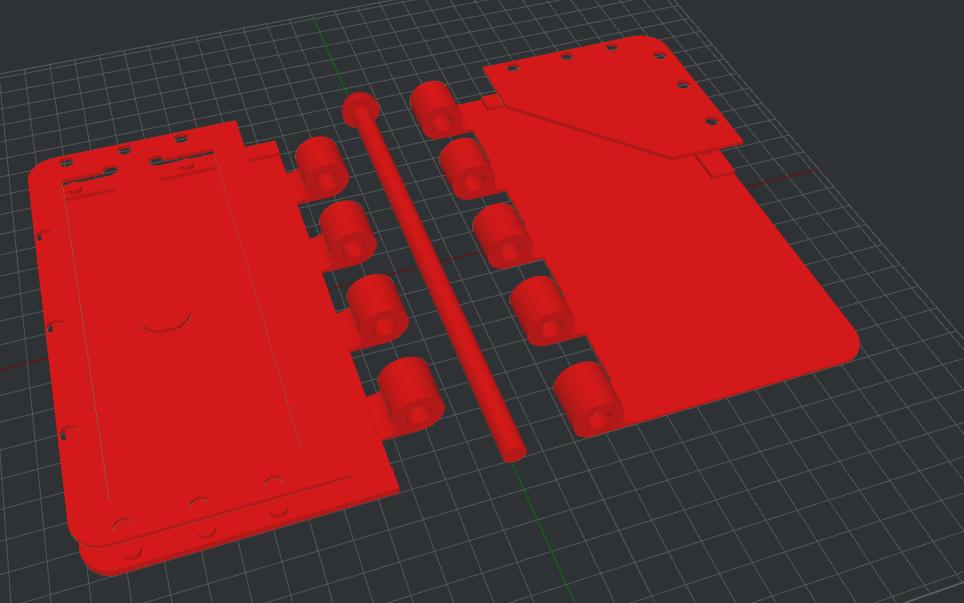

- Work the .STL file with reverse engineering and obtain the .STEP file

- Create the NX Cam program and define the machining process

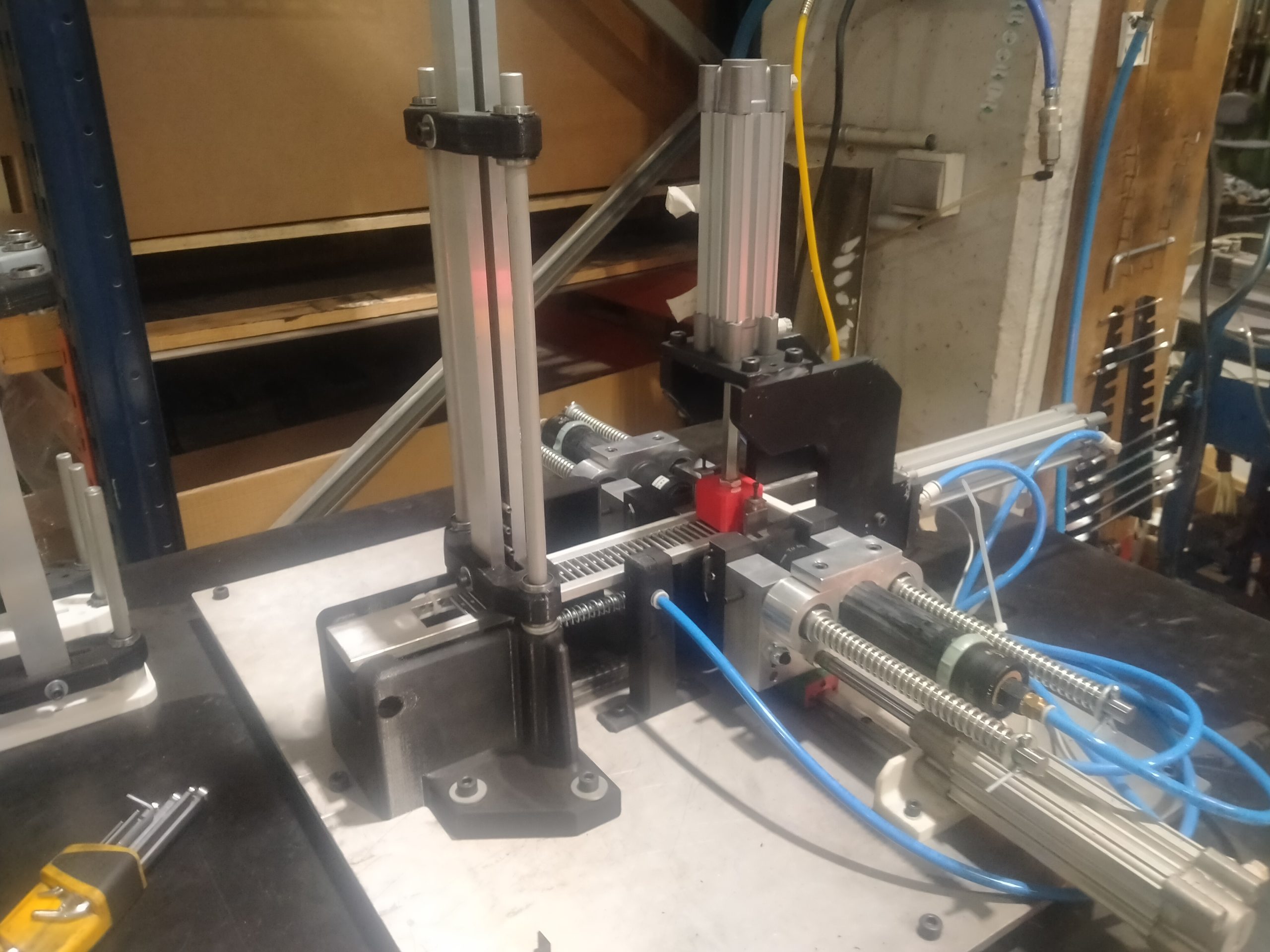

- Design and manufacture the tooling necessary for machining the part

- Machining using the necessary means to work at high speed

- Re-scan and compare the parts obtained

Link