- Duration: 54 hours

- Year: 2023

- Participants: Perilan World + Oteitza Eskola Politeknikoa

- Industry 4.0 and advanced manufacturing

Project description

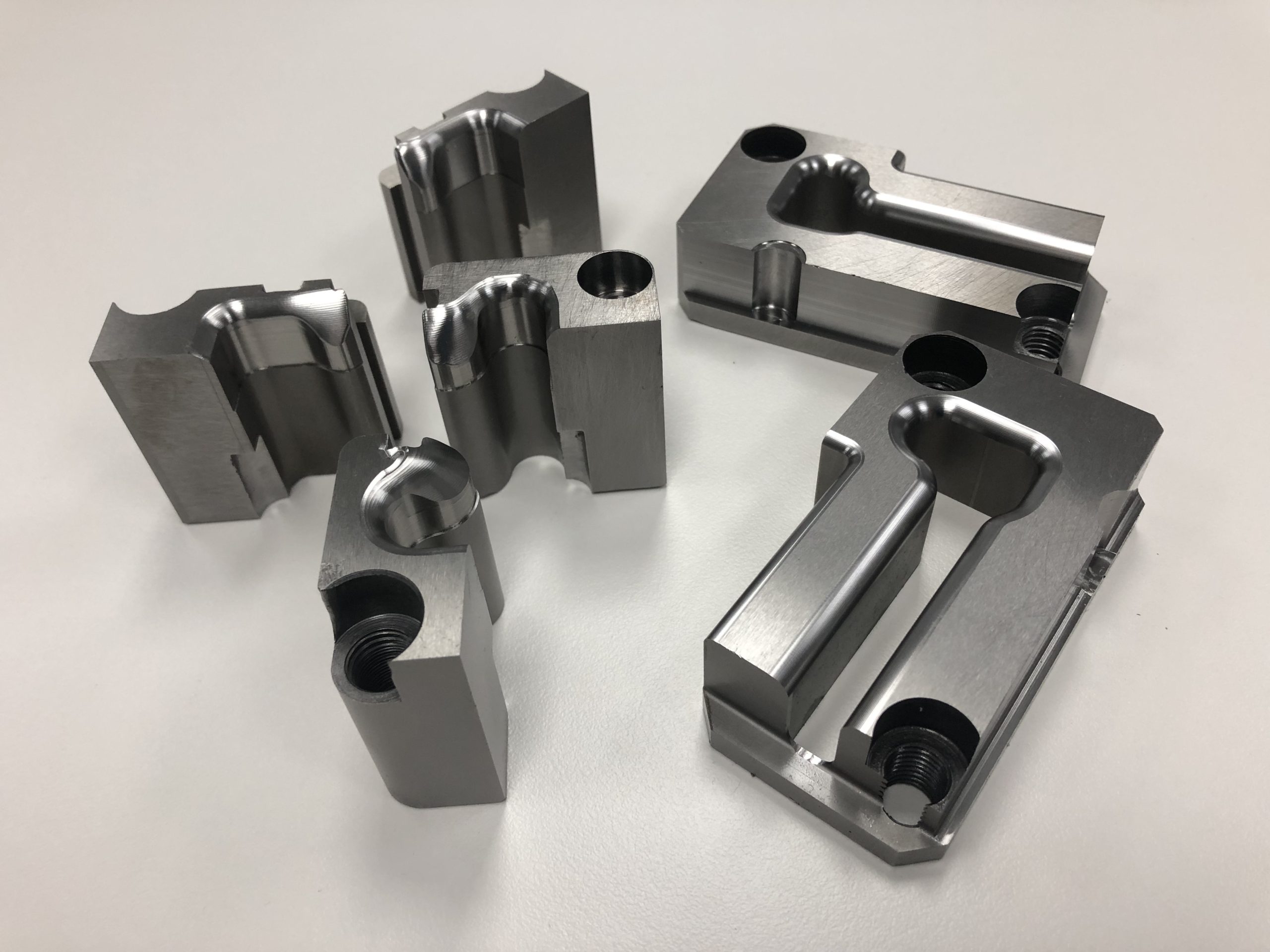

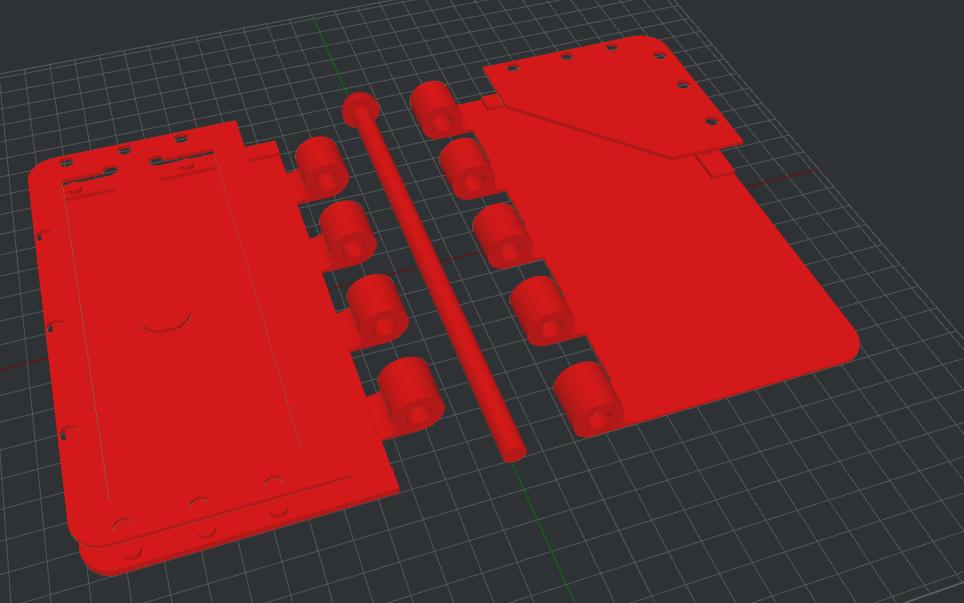

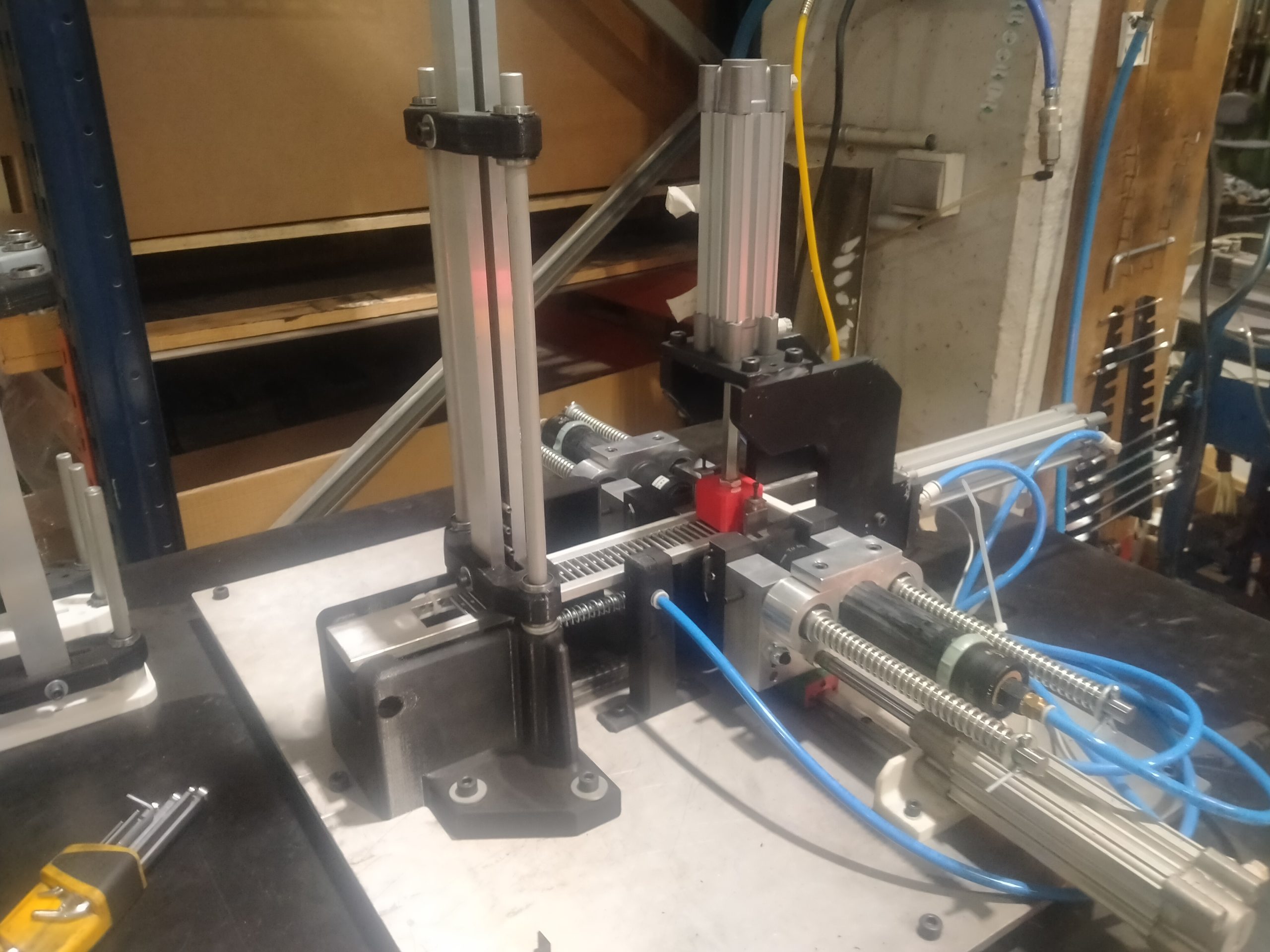

After developing a geometric study of the parts that make up the project, we have developed a suitable process for their manufacture in Oteitza. Subsequently, using the KONDIA HS-1000 milling machine, parts and their tooling were manufactured using high speed.

Given the role of the parts, they were hardened and tempered to achieve the required level of hardness, specifically 58 HRC. In order to achieve a defined geometry, the ONA wire EDM machine had to be used to finish the parts not machined with revolving tools.

The parts made were Upper_1_blade (5 pcs), Lower_1_blade (5 pcs), Anvil_1 (5 pcs), Former_1 (3 pcs), Upper_long_blade (5 pcs), Former_2 (3 pcs), Upper_long_blade (5 pcs), Shaper_2 (3 pcs), Upper_Long_2_Knife (5 pcs), Lower_2_Knife (5 pcs), Anvil_2 (5 pcs), Shaper_1_Long (3 pcs).

The main difficulties have been the small size of the pieces, the necessary hardness and their design.

Tasks Performed

- Analyse the geometries of the parts and define the process for each part

- Tooling design

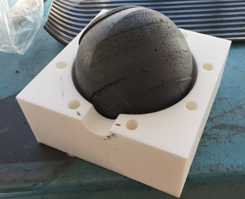

- Prepare the materials (they must be of good hardenability, in this case F-521)

- CAM programming

- Carry out all the machining

- Hardening and tempering treatment

- Carrying out the final machining in wire EDM