- Duration: 5 months

- Year: 2016

- Participants: OTEITZA + GKN DRIVELINE

- Industry 4.0 and advanced manufacturing

Project objectives

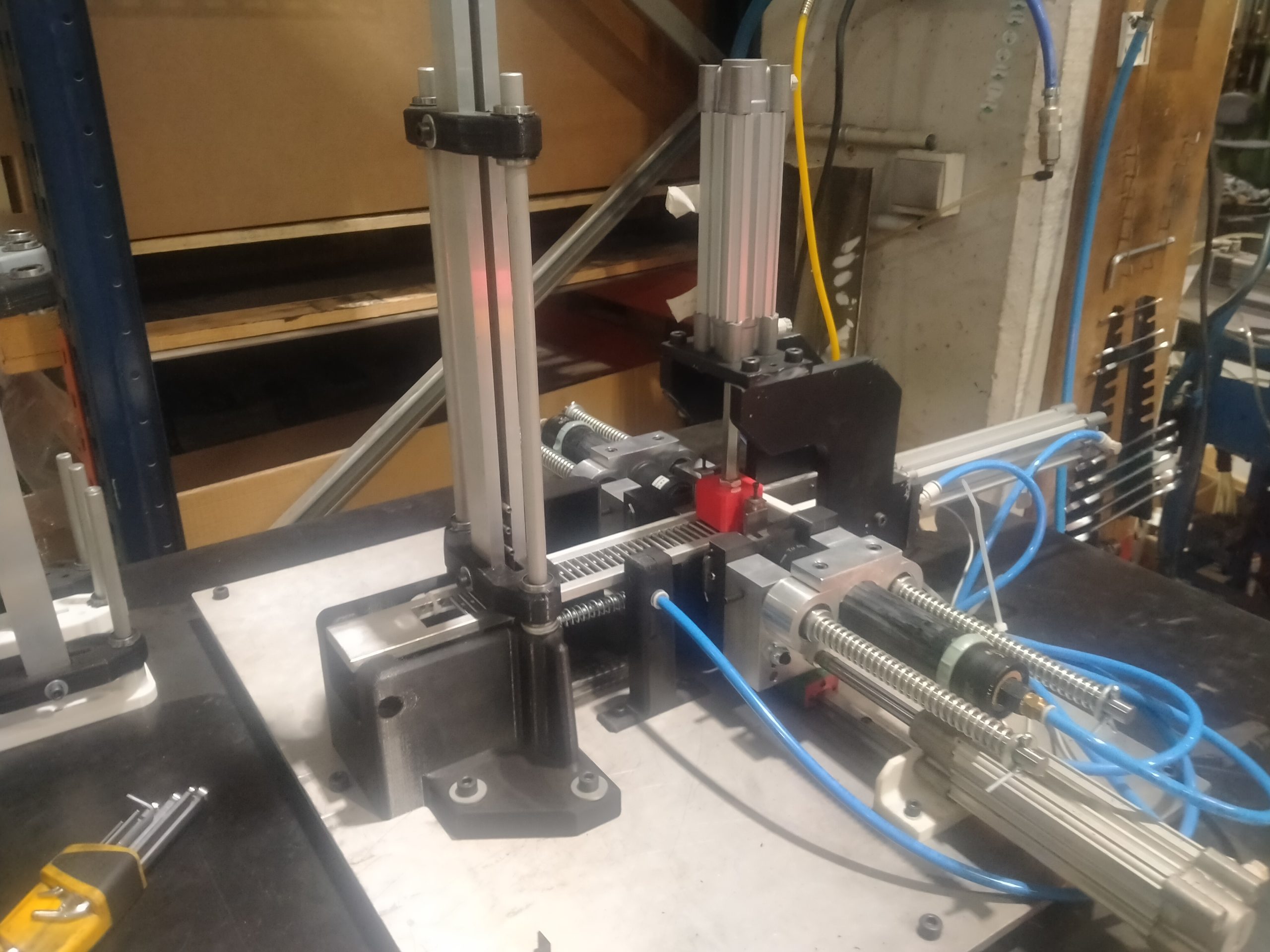

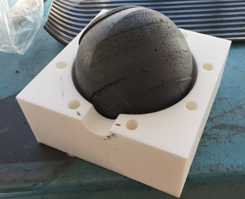

Until now, the company used to deburr the lampshades by hand. An automatic machine has been designed and manufactured in its entirety to improve both the process and the ergonomics and work quality of the operators. The machine process consists of pressing the bimanual, lowering the protection panel, starting the rotation of the tool and part, and then lowering the head to make contact with the part by deburring it. At the end of the cycle, the workpiece table automatically moves to remove the workpiece and insert the new one.

Tasks performed

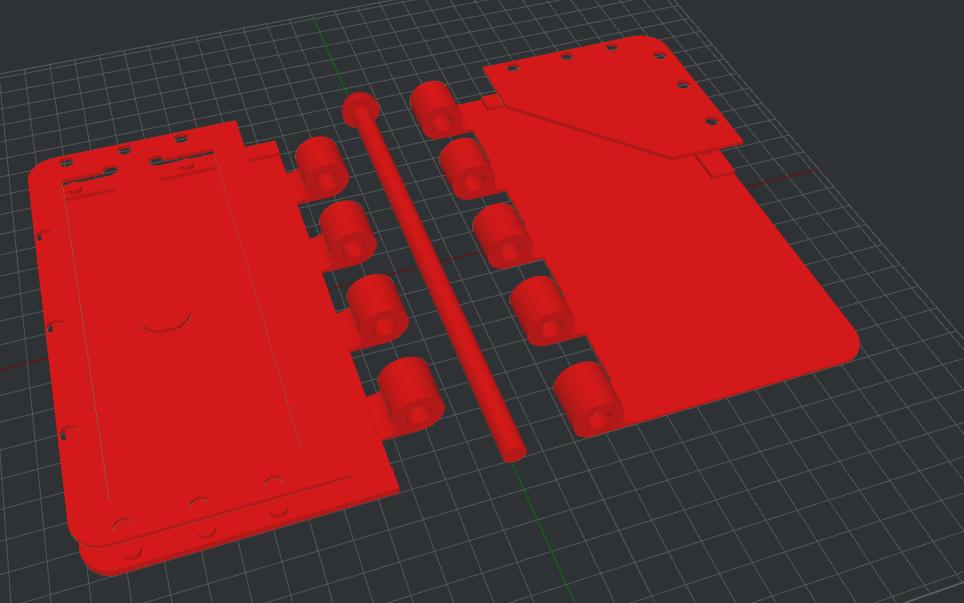

- Develop the design of the machine and agree it with the company.

- Design the electrical panel and the pneumatic maneuvers.

- Purchase a second-hand drill.

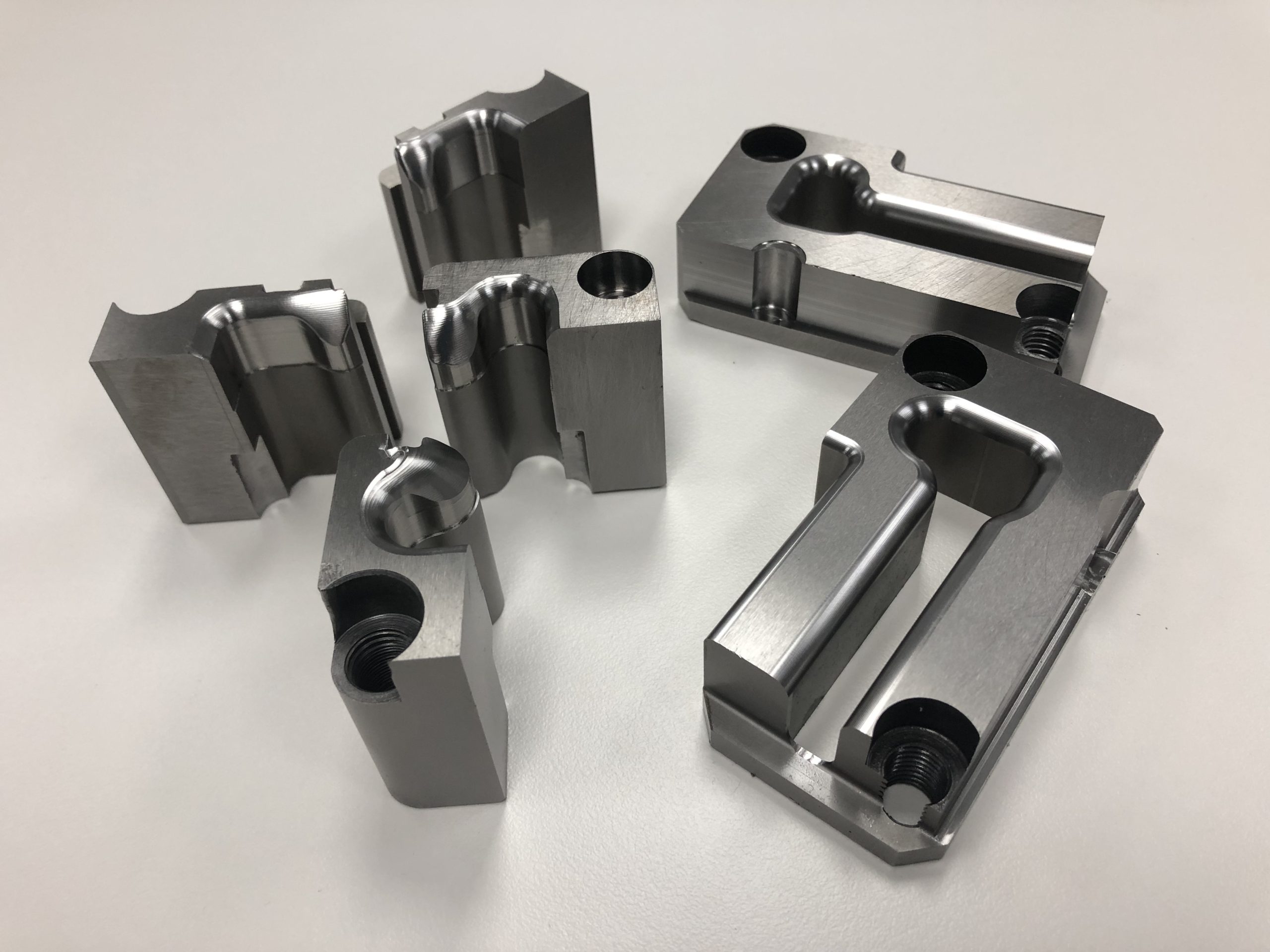

- Carry out the necessary manufacturing processes, first, modifying the drill and second, manufacturing parts for automation.

- Carry out the entire assembly in compliance with the specifications.

- Execution of pneumatic and electrical assemblies.

- Painting according to the company's requirements.