- Duration: 6 months

- Year: 2023

- Participants: ZULAIBAR + BATZ S.COOP.

- Industry 4.0 and advanced manufacturing

Project objectives

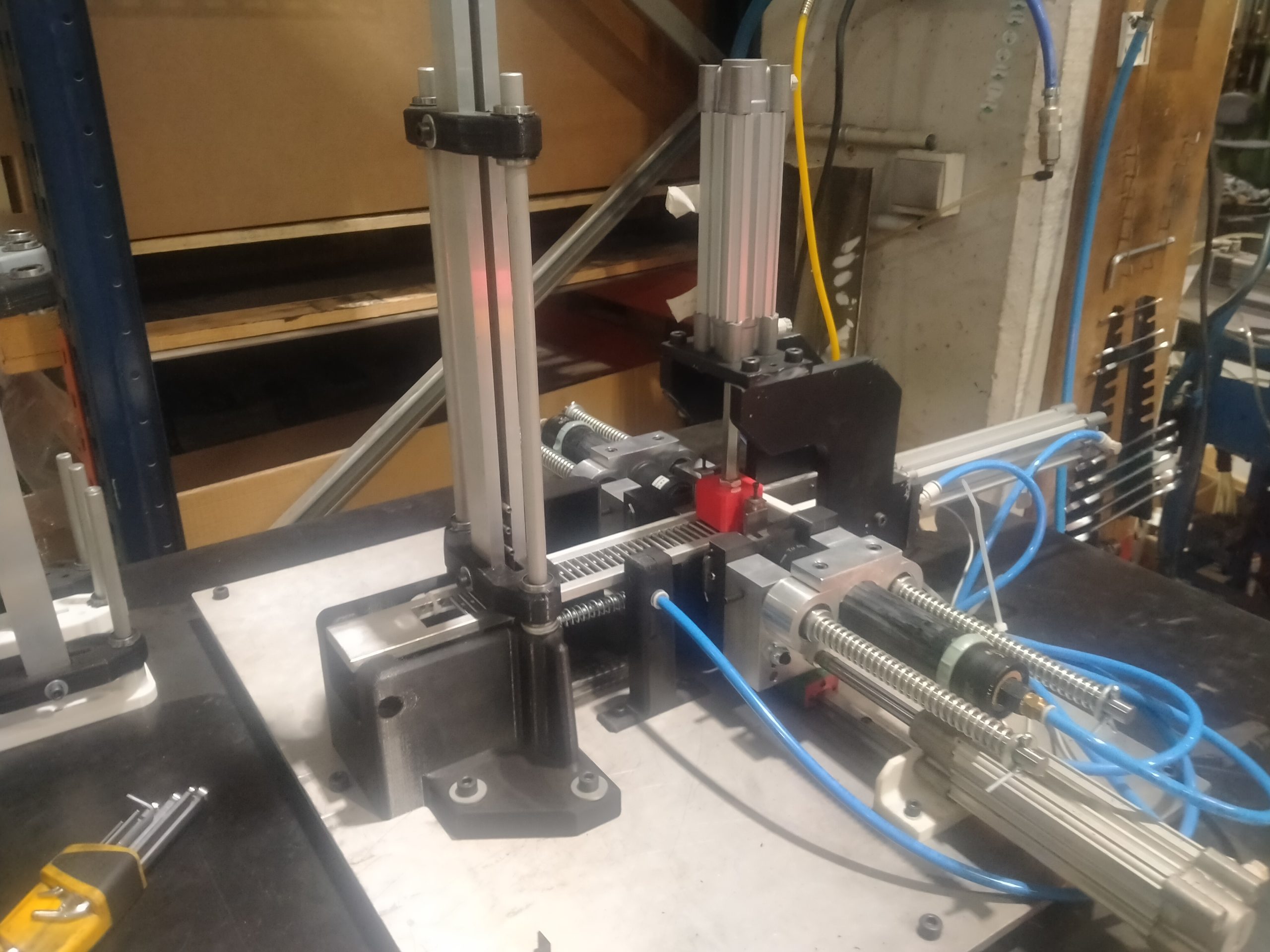

In the manufacturing line where active aerodynamics components are assembled in the automotive systems business, a sensor system is used when assembling the fins that make up the system, which approaches the fin and ensures its position. Since it is not a fixed position, the position in which the fin should step or rest is not well measured. This results in non-conforming parts leaving the manufacturing line, thus creating non-conformities in the quality process.

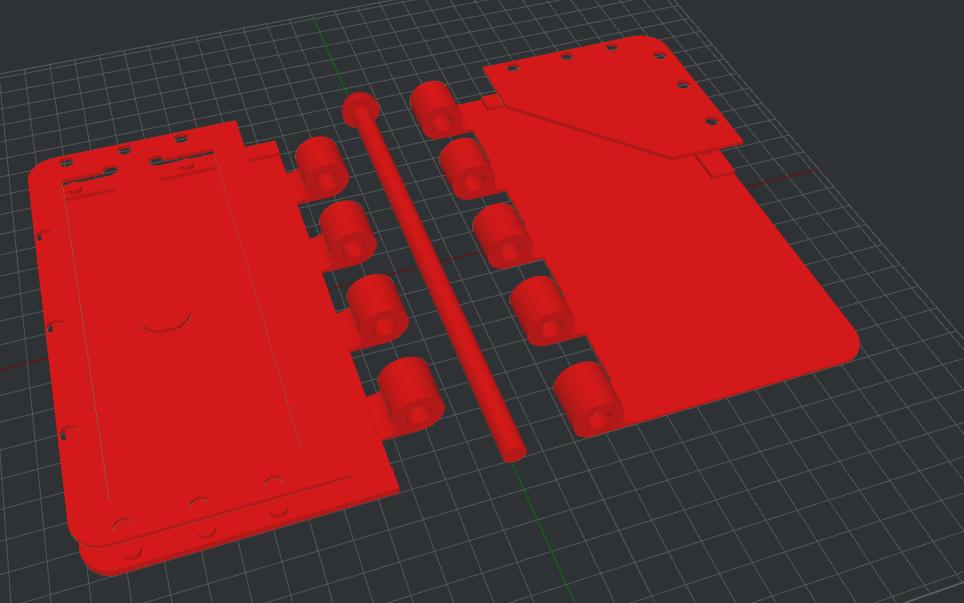

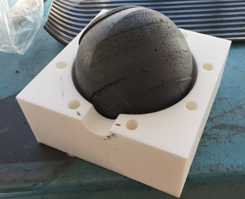

Once the problem has been analyzed, a simple system has been designed, consisting of different easily machinable parts, with which a problem that has been the key to a manufacturing line has been addressed.

With the homogeneous and repetitive position guaranteed by this new system, the position of the fins is 100% controlled and nonconformities have decreased significantly.

Tasks performed

- Design analysis.

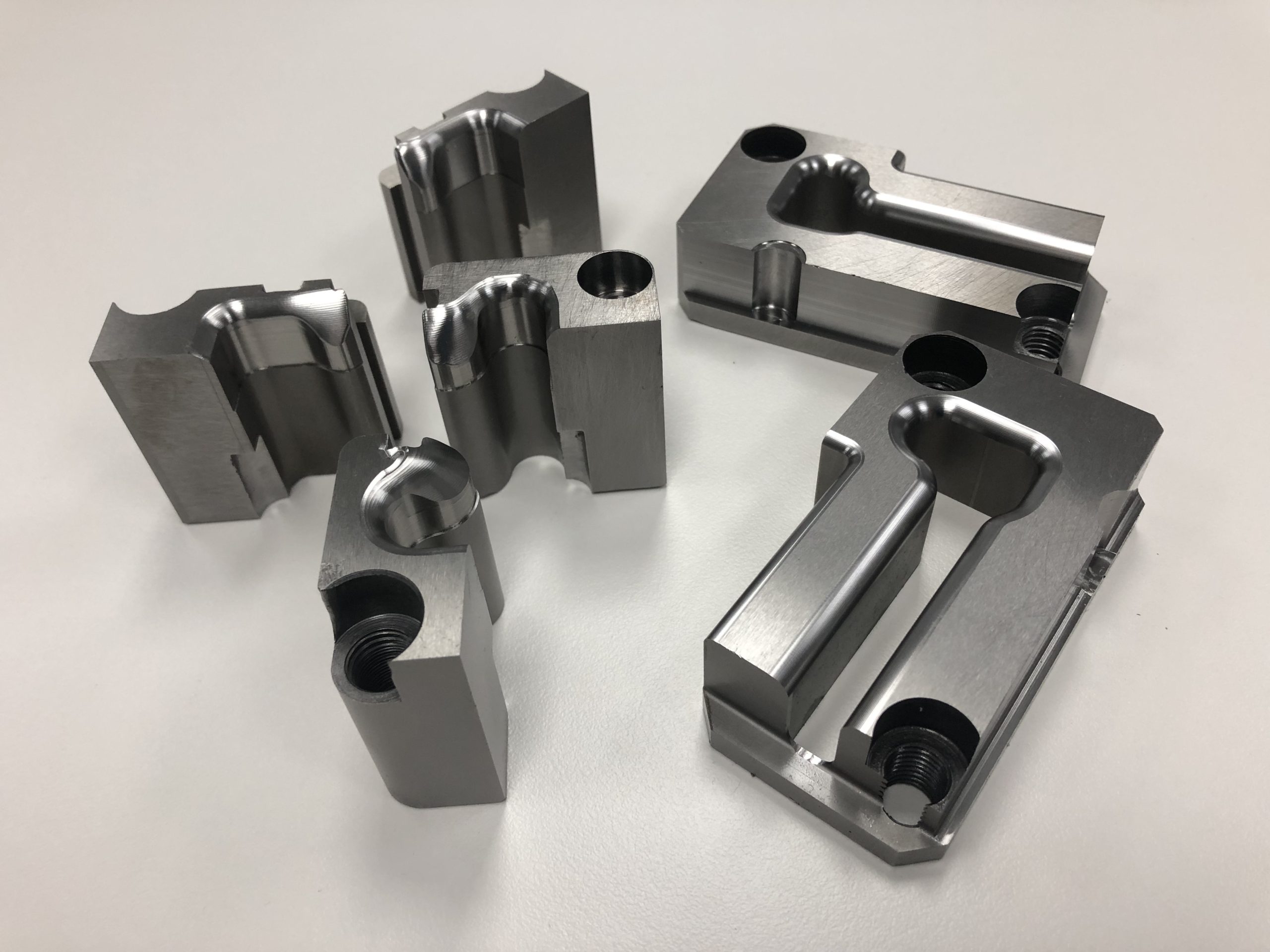

- Preparation of the machining of parts.

- Machining of parts.

- Treatment of parts.

- System assembly.