- Duration: 6 months

- Year: 2021

- Participants: SALESIANOS DEUSTO + SUESA

- Industry 4.0 and advanced manufacturing

Project objectives

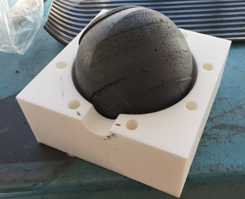

The company was carrying out a manual process of mixing epoxy with hardener to fill a series of transformers. They needed to improve that process to run it in a more automated and cleaner way.

Tasks performed

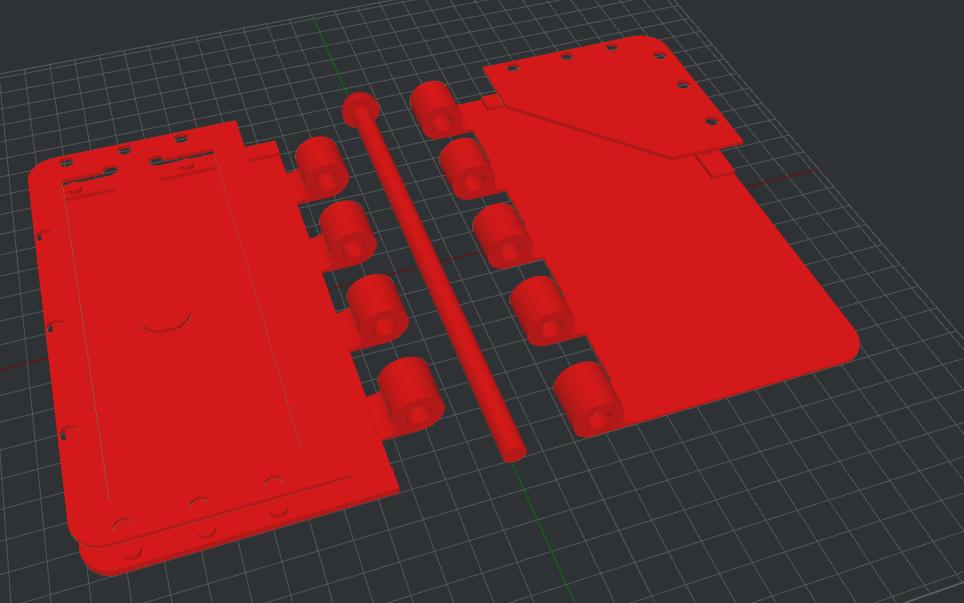

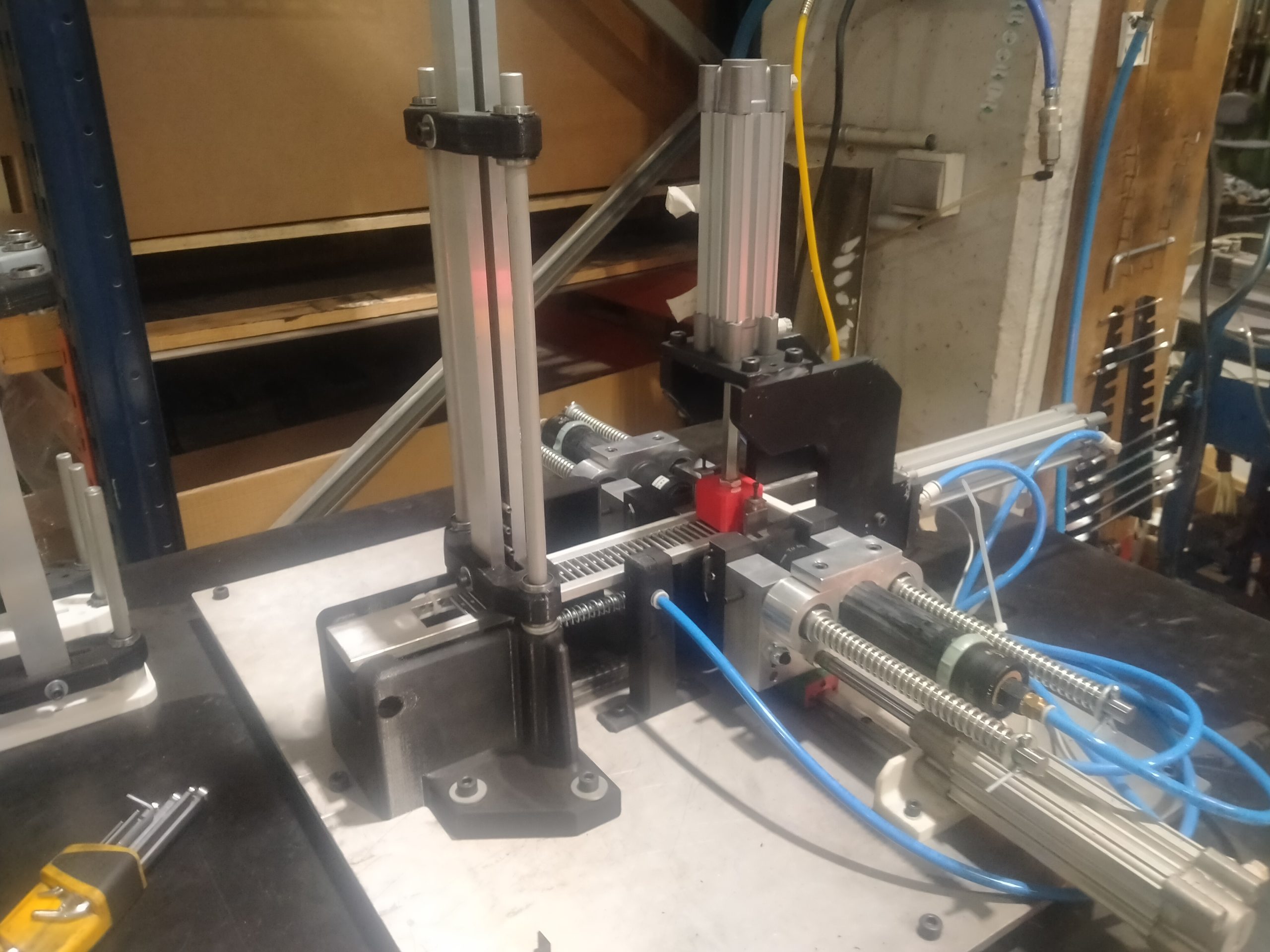

- Design a system based on a vat with a motor that moves a propeller to automatically stir the epoxy and hardener to be mixed.

- To add the components to facilitate the operator to fill the transformers in a clean way (dispensing gun) and to remove as much air as possible (air inlet systems).

- Test to ensure that each component is made of materials compatible with epoxy and can be easily disassembled for later cleaning.