- Duration: 2 meses

- Year: 2018

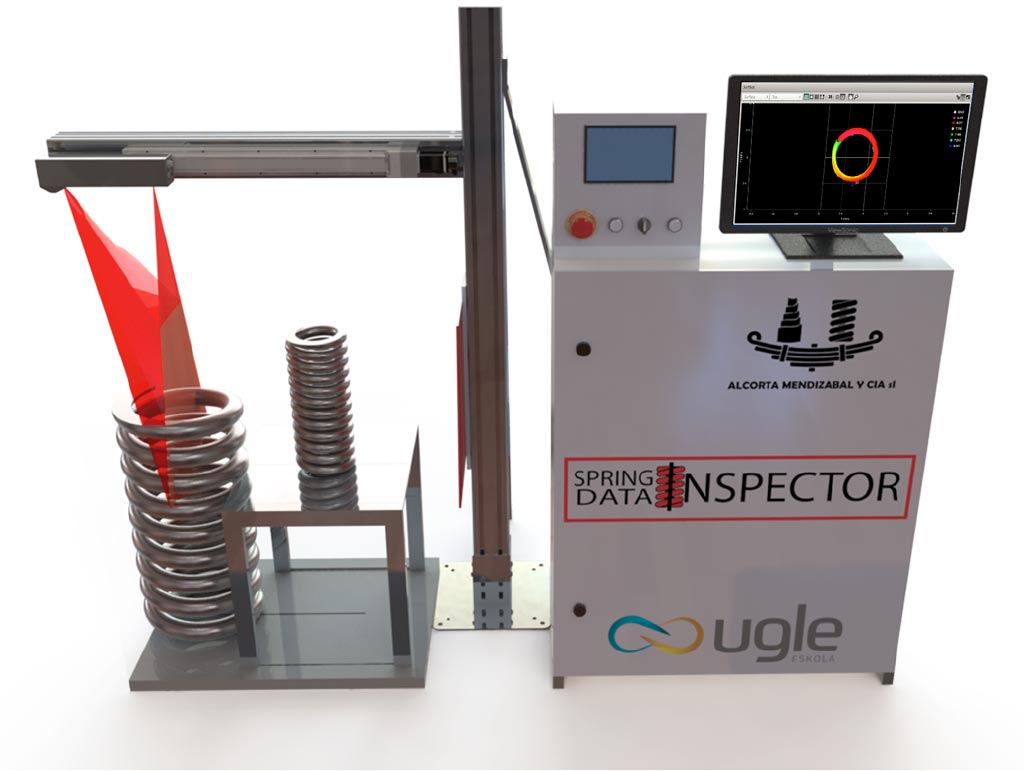

- Participants: Alcorta, Mendizabal y Cia. S.L. + UGLE

- Sector: Industria 4. 0 / Conectividad

Project objectives

Currently the only way to measure the springs that are produced in the company Alcorta, Mendizabal is controlled manually, by contact, and it is the worker who must decide if each piece is valid or not.

The objective of the project is that all the springs of the process can be inspected in a continuous production process, by means of a non-contact measurement system, collecting digital information.

Tasks performed

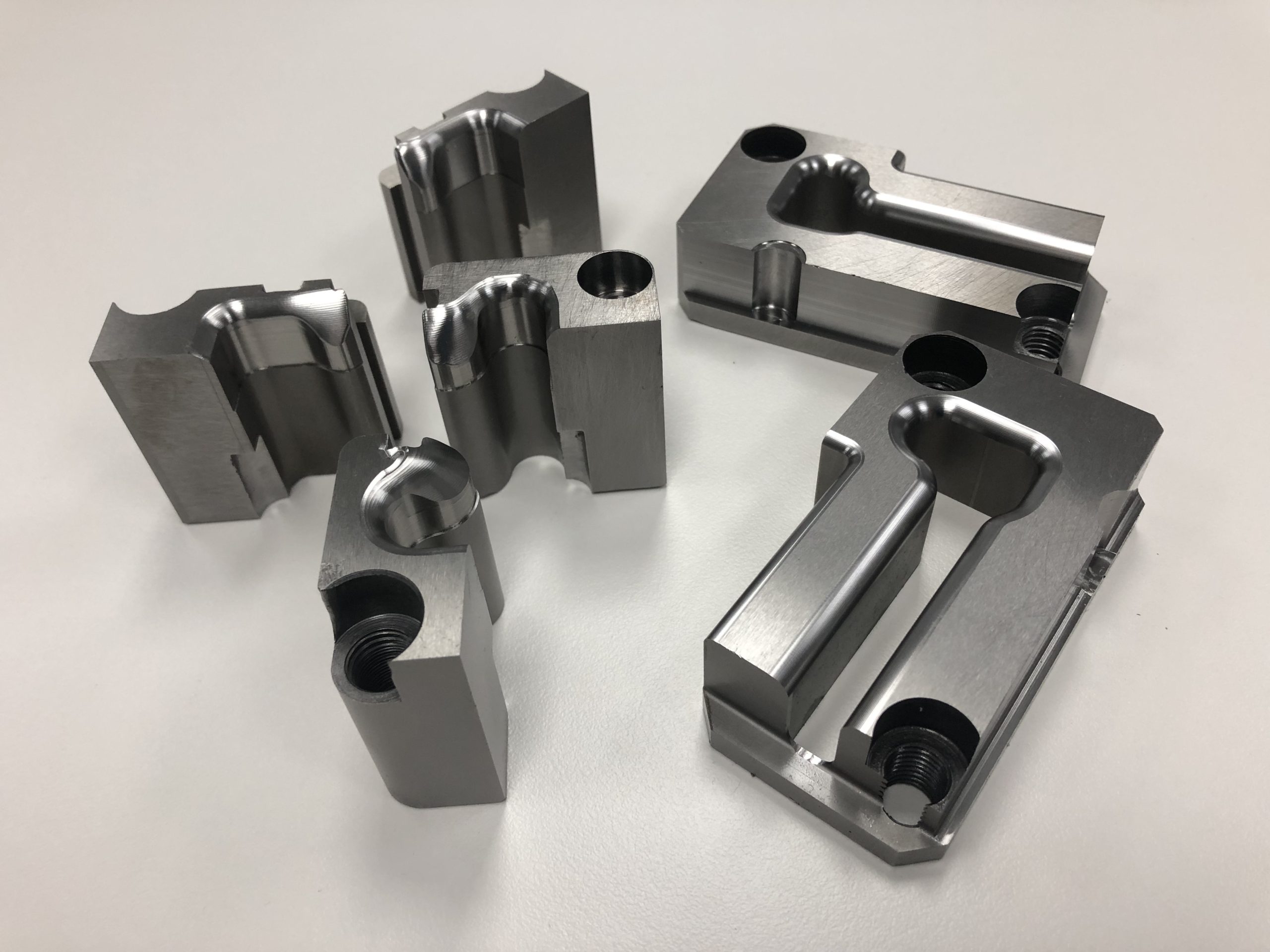

- Analysis of the dimensional and geometric characteristics of the springs provided by the client

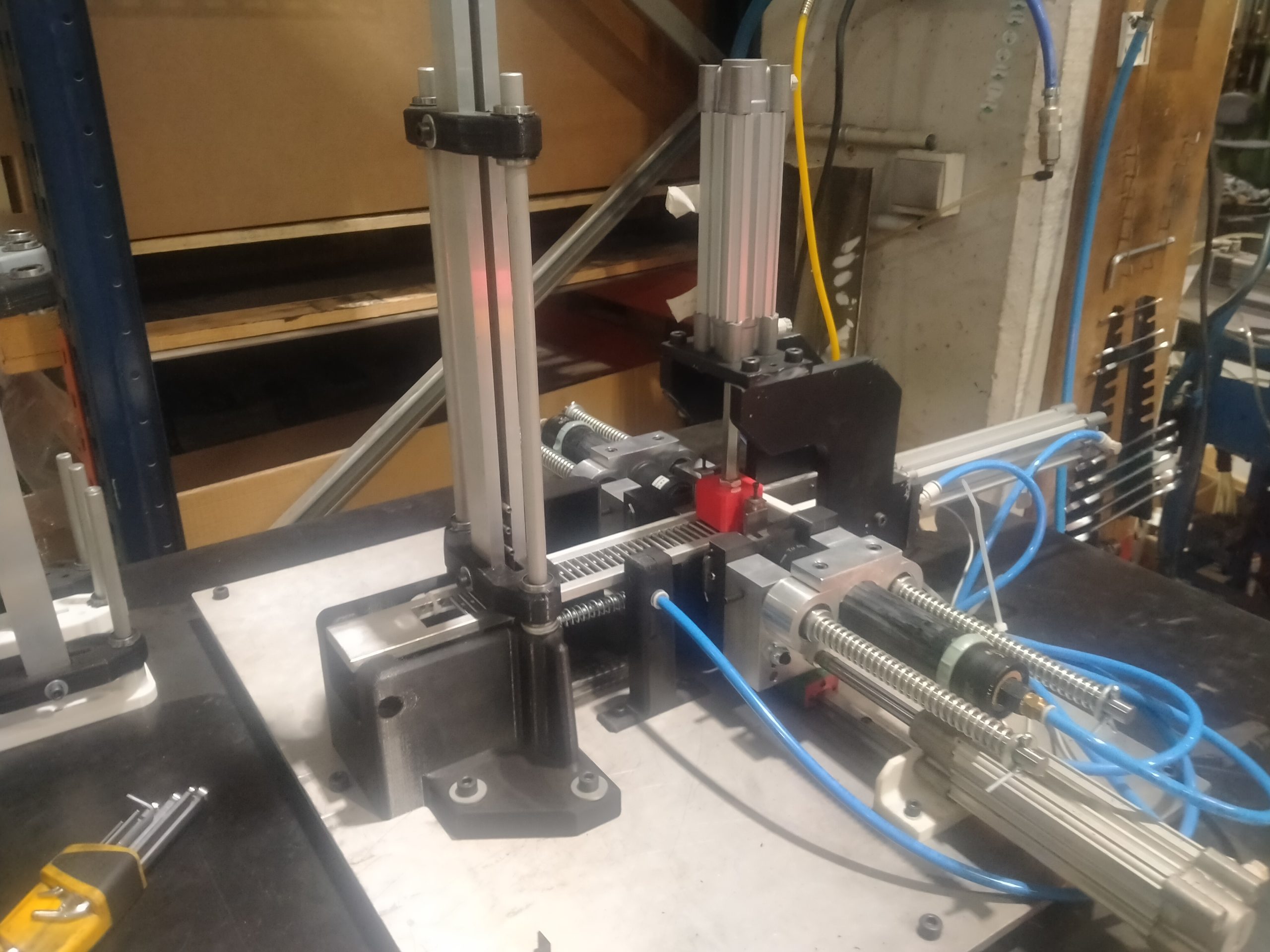

- Scanner selection according to product family tolerances (GOCATOR 2150)

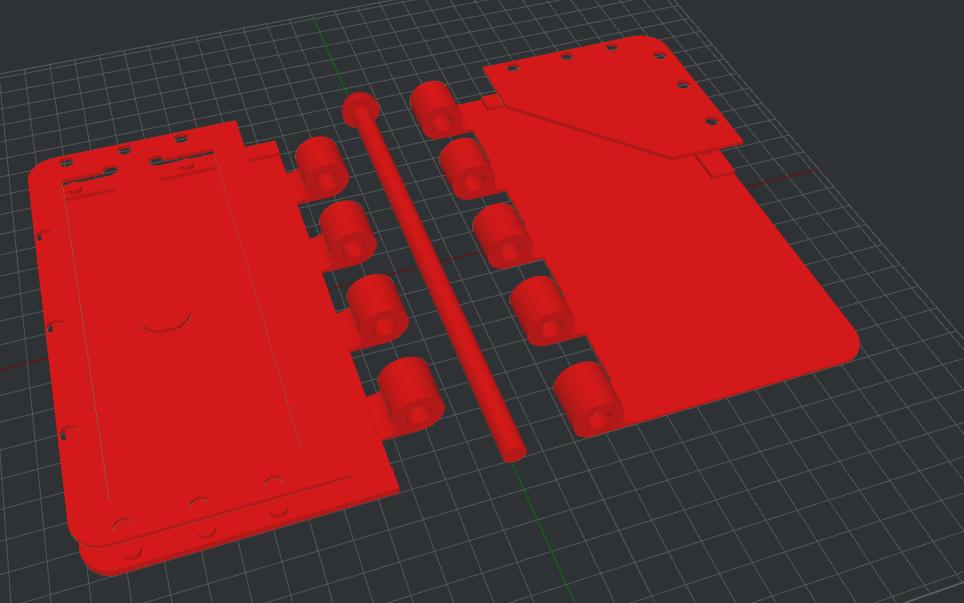

- Implement the programming of an automaton of the manufacturer OMRON to be able to integrate a touch HMI (Human Interface Machine).

- The information of the input and output data will be read and a storage system will be enabled in some database in the cloud of Alcorta and Mendizabal