- Duration: 6 months

- Year: 2020

- Participants: IRUNGO LASALLE + CIRLAN SL

- Industry 4.0 and advanced manufacturing

Project objectives

The company CIRLAN, S.L. offers a wide range of printed circuits for LED technology, both single-sided, double-sided without metallizing and metal core circuits.

One of the fundamental pillars of the company is the continuous improvement of its manufacturing processes, which implies that both the collection times of replacement material and the machine downtimes are as short as possible. It is for this reason that the company decides to contact the Irungo La Salle professional school to be able to solve a critical point in its manufacturing process due to a high stop time rate.

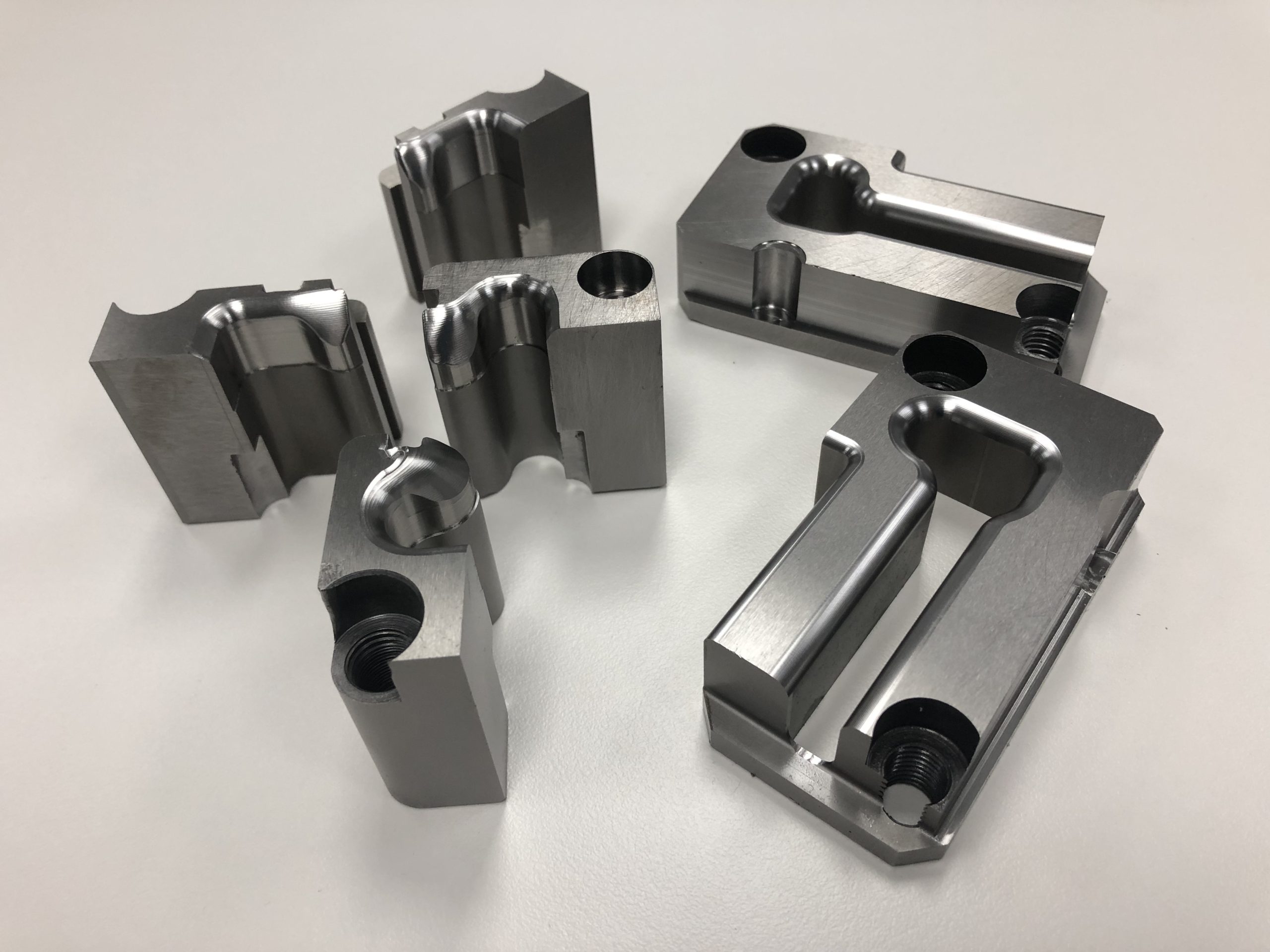

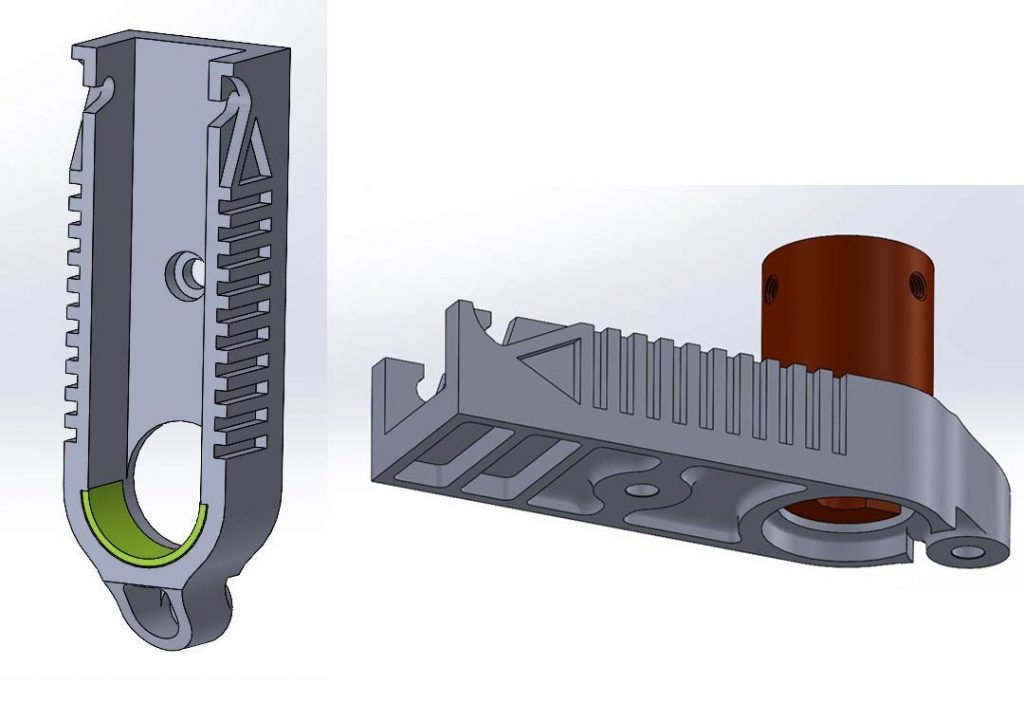

The objective of the collaboration is the redesign of roller support parts where the printed circuit boards are treated and thus be able to minimize these times.

When analyzing the problem, a metal-plastic contact was observed that involved the breakage of the support pieces. That is, the metal toe caps of the rollers in their rotation produced friction and wear in the plastic parts of the support.

Tasks performed

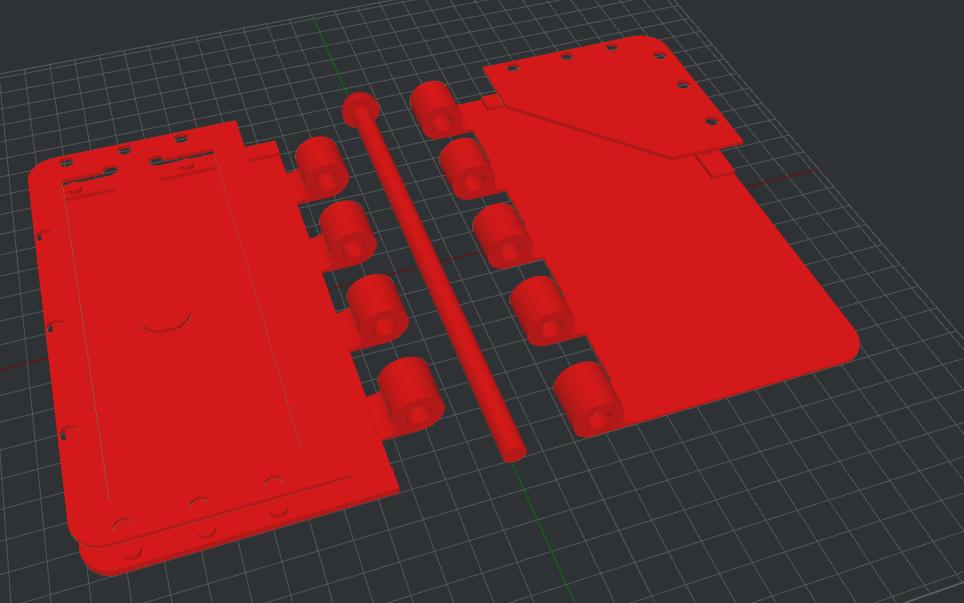

- 3D creation of the support model and the roller toe.

- Dimensional and tribological analysis.

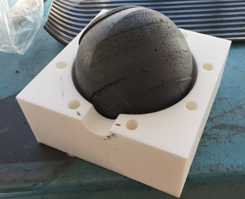

- Proposal for inclusion in the plastic support of a half metal cap with Teflon dispersion.

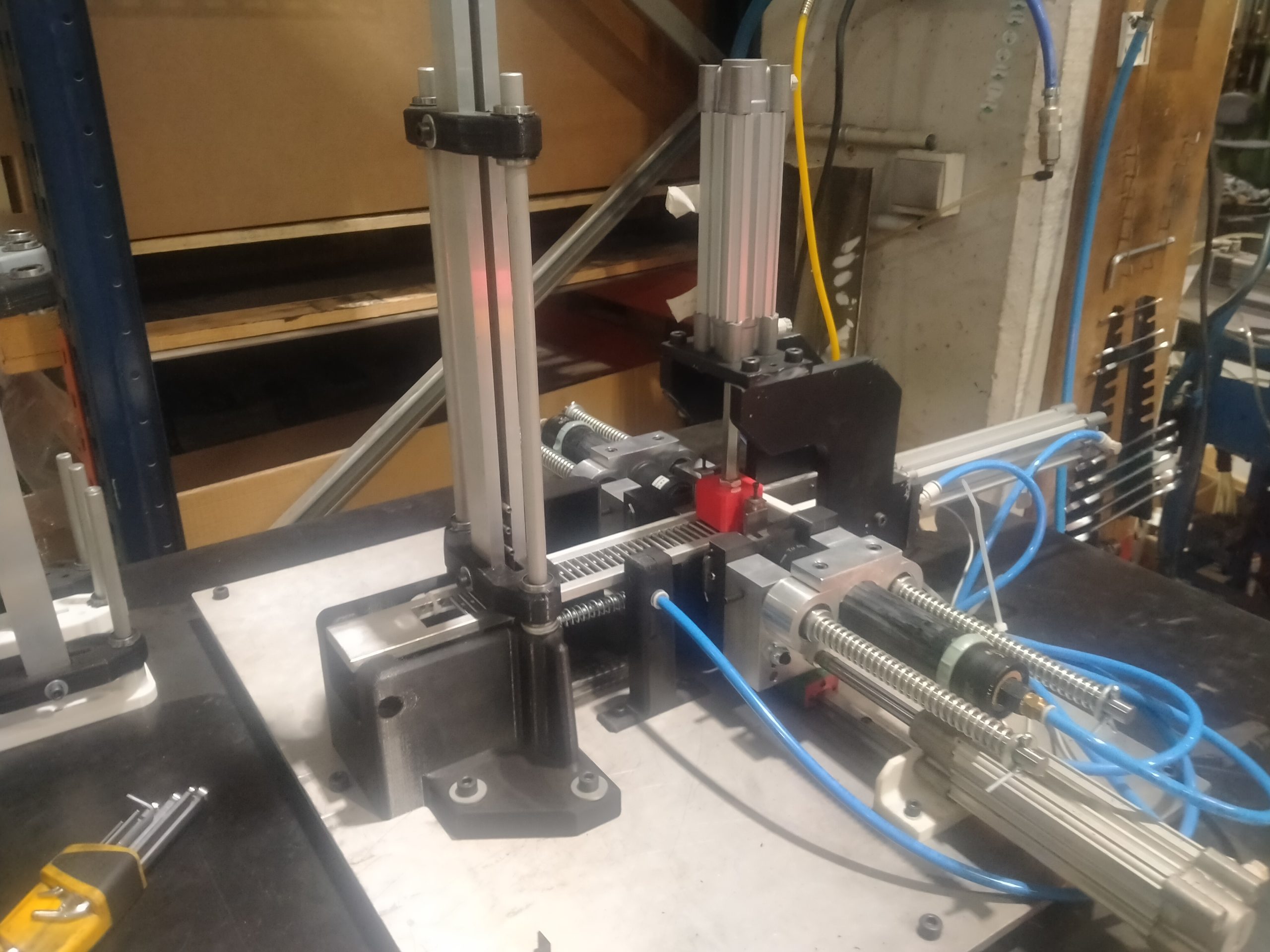

- Manufacture of prototypes and analysis of the operation of several samples.

- Modification of the bush locking system.

- Increase in thickness of the bushing support wall.

- Generation of new drawings and models for additive manufacturing.

- Manufacture of prototypes and analysis of the operation of new samples.

- Modification of the design simplifying non-functional parts.

- Validation of the project.