- Duration: 2 months

- Urtea: 2019

- Participants: ELORRIETA ERREKA MARI + DECOLETAJE Y FIJACIÓN SL

- Industry 4.0 and advanced manufacturing

Project objectives

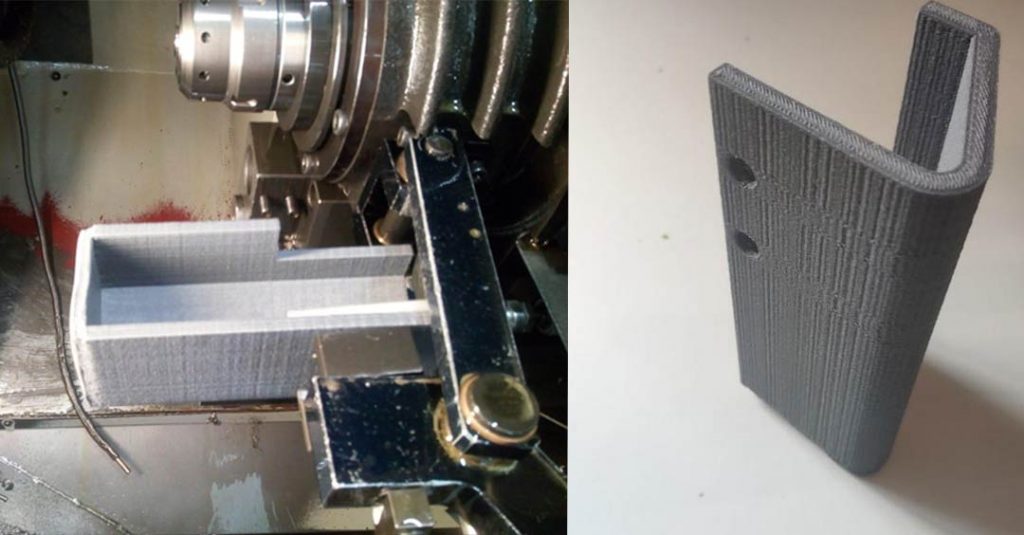

Due to the materials and manufacturing conditions, the parts when manufactured and collected in metal boxes, tend to rust. At the same time, when collected in a container whose hardness is higher than that of the collected piece, these usually suffer scratches and / or small deformations, causing them to have a lower quality than the one designed or even being able to become unsuitable for marketing, with the consequent loss of income.

Faced with this problem, the company Decoletaje y Fijación SL believes it is necessary to carry out a study to look for alternatives that avoid the oxidation and marking of these parts, thus optimizing the manufacturing process.

Tasks performed

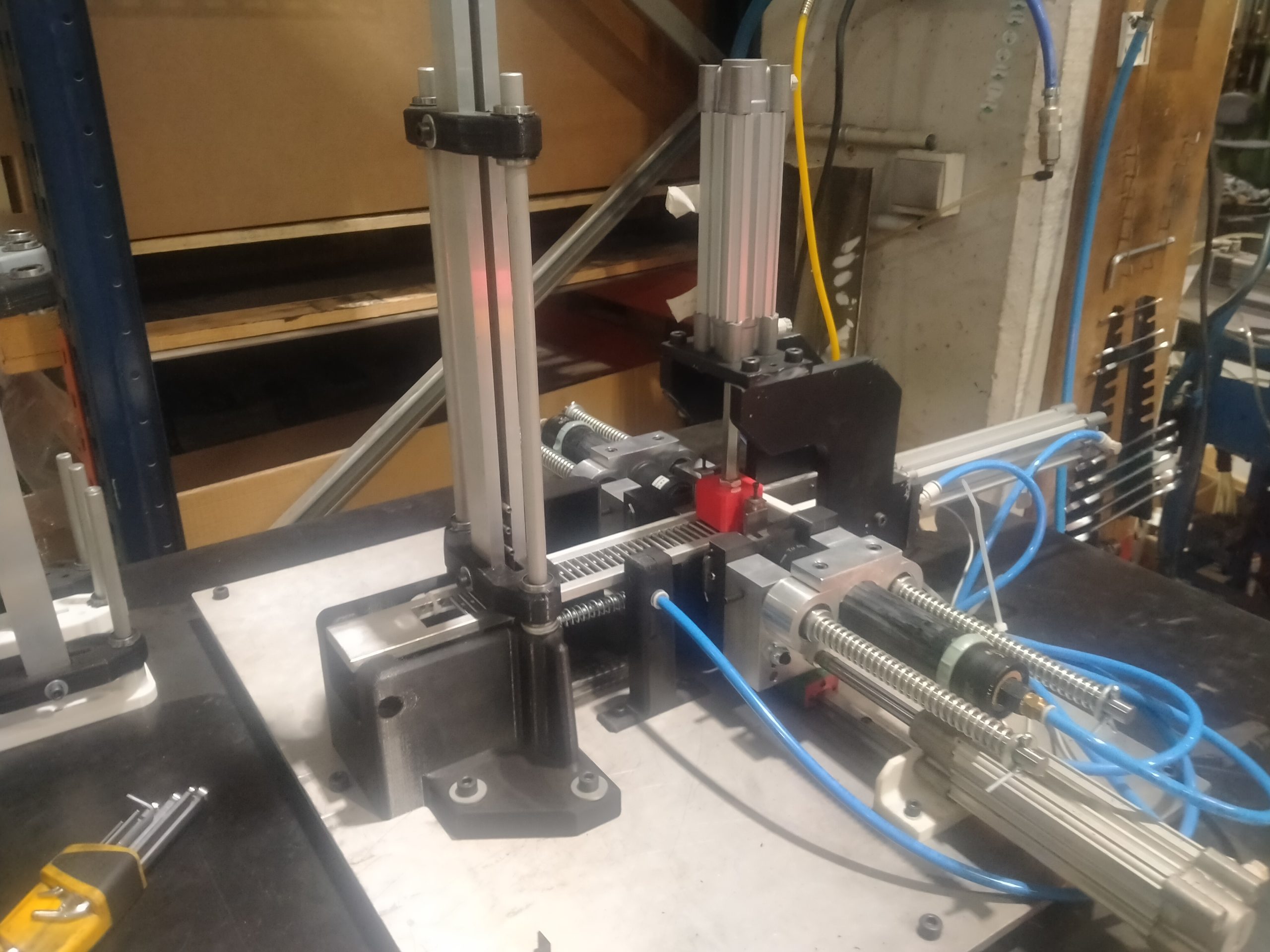

- Carrying out a study of the current systems of collection of parts in the automatic lathes.

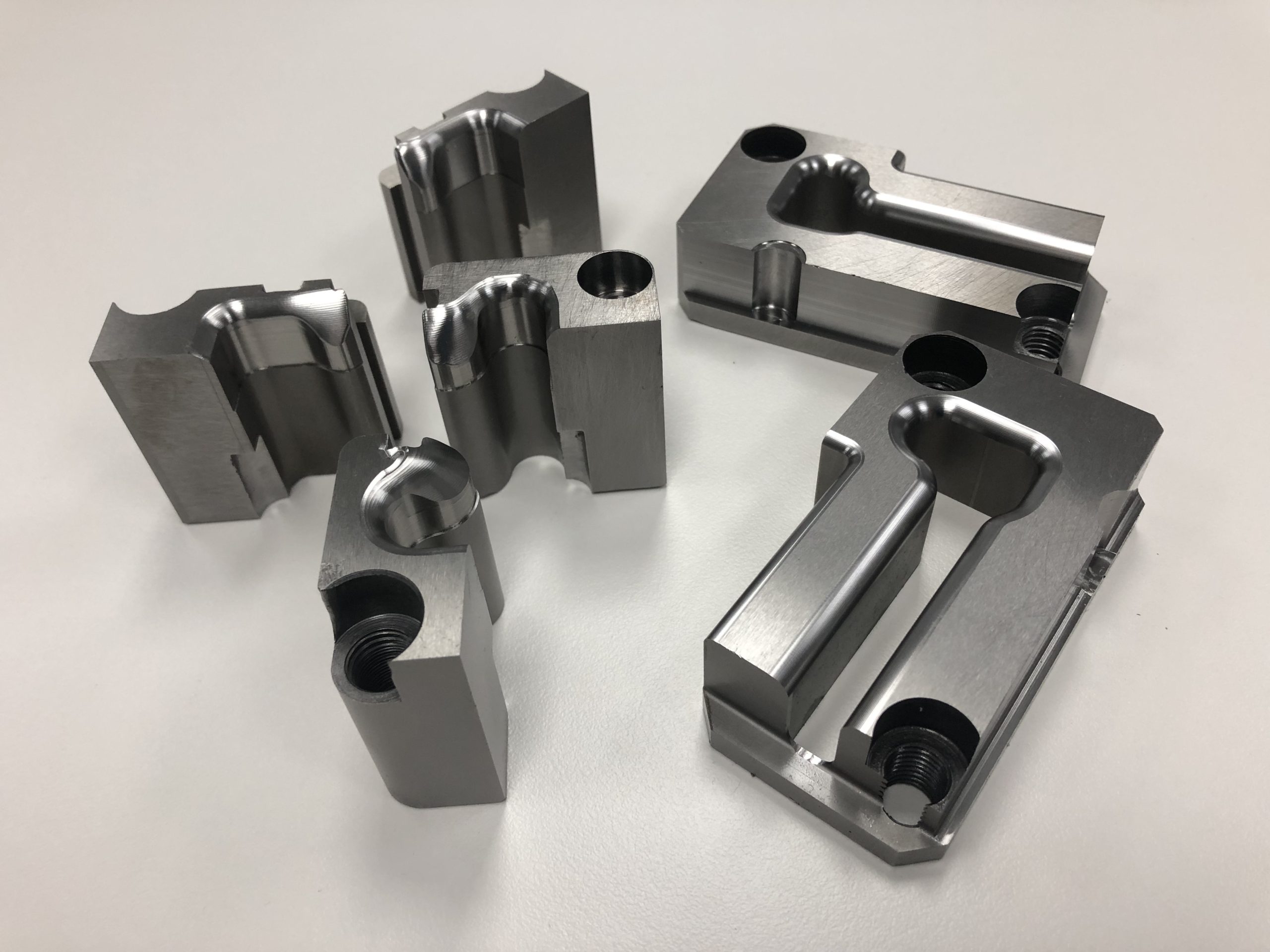

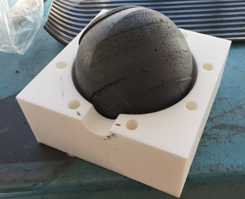

- Study of different materials that optimize the design of the component.

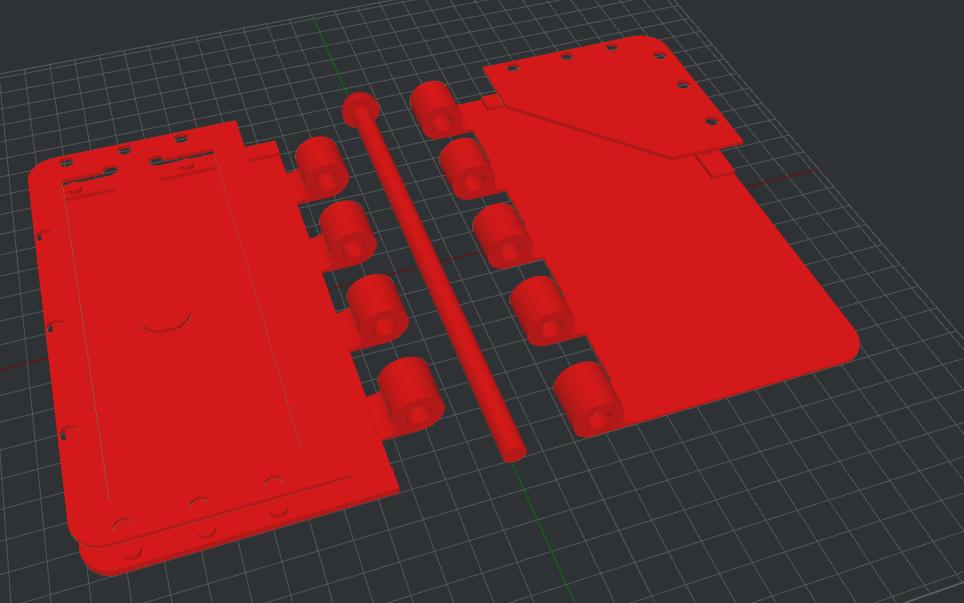

- Design of the collection component.

- Generation of digital plans for its manufacture.

- Testing of the part and redesign for its optimization.

- Manufacture and assembly of the component.