- Duration: 6 months

- Year: 2019

- Participants: IMH + INDUSTRIAS BETA

- Industry 4.0 and advanced manufacturing

Project objectives

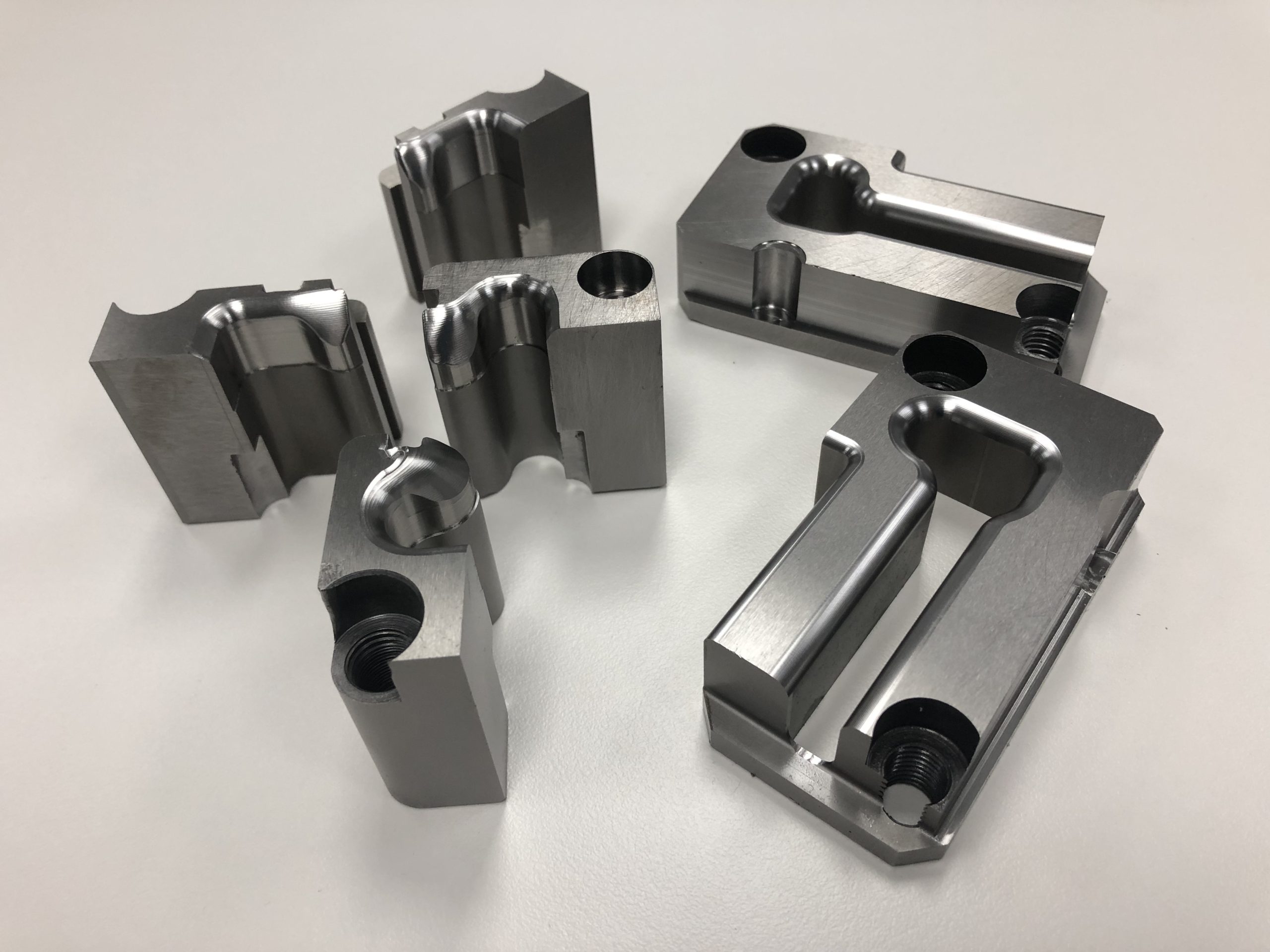

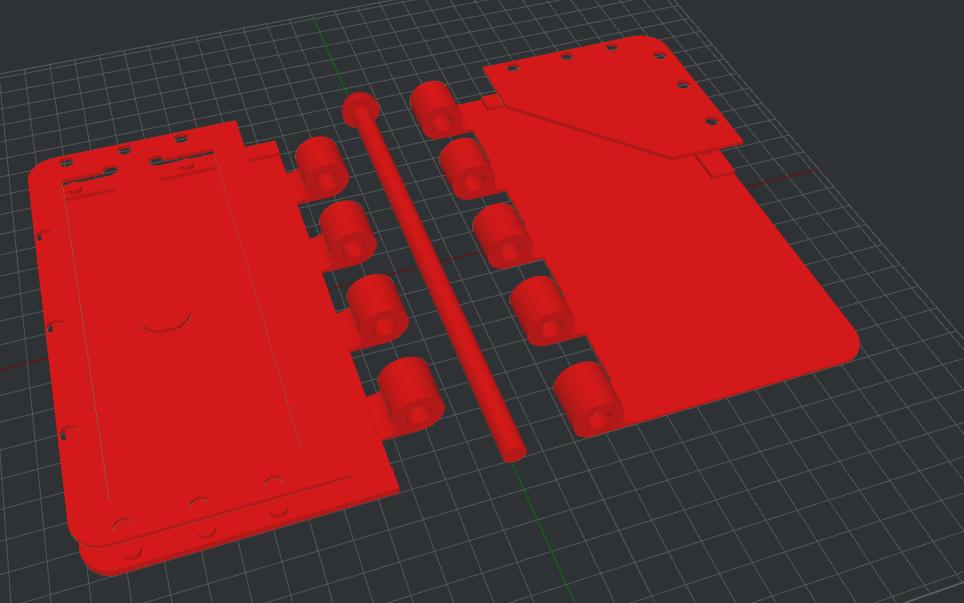

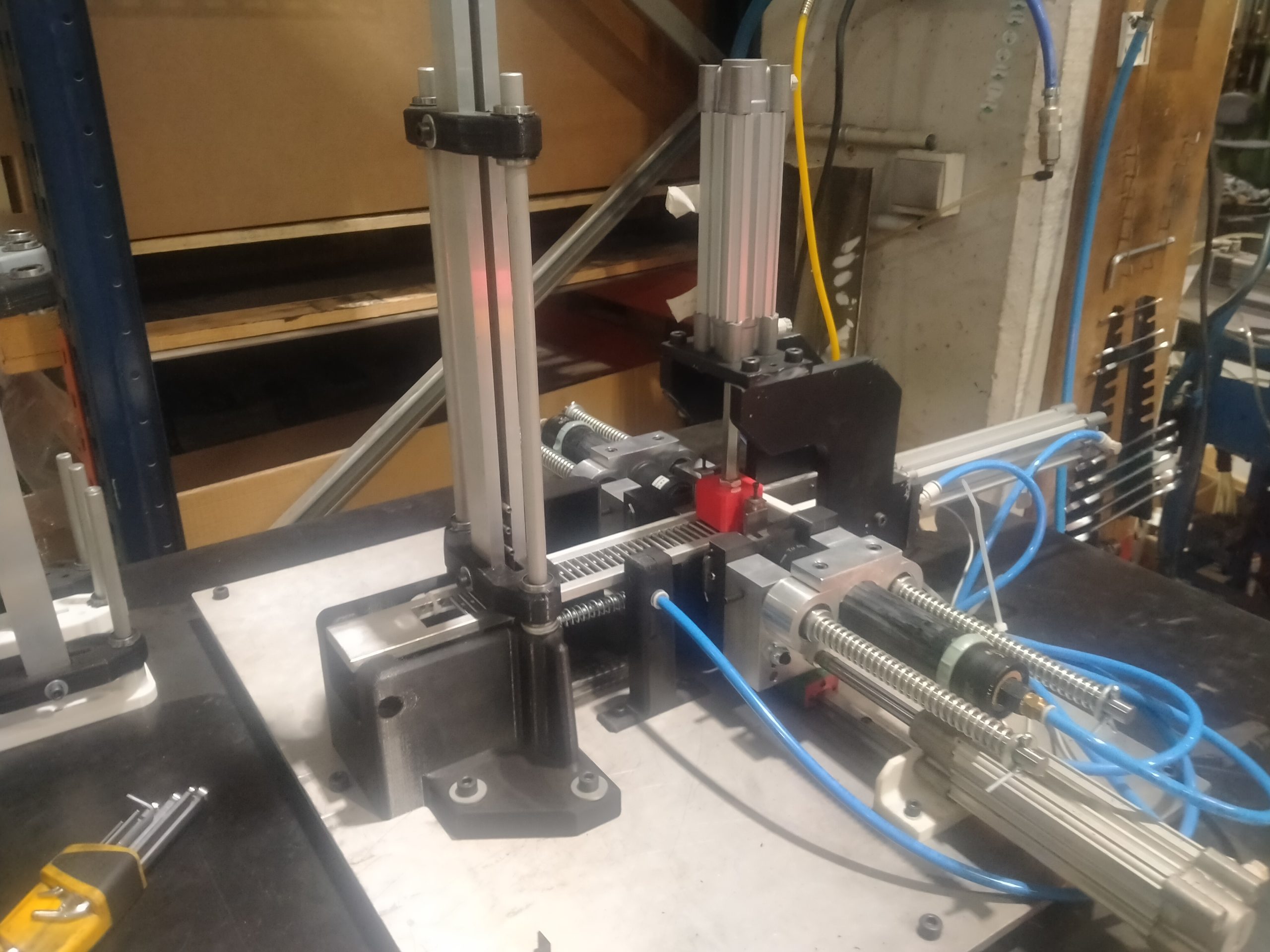

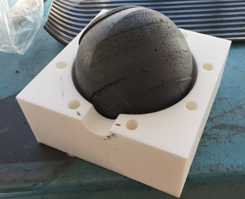

A company that works for the automotive sector achieves the production of a specific part for the coming years. This reference is generated by cold forging, after 6 consecutive steps, in which the transfer from one position to another is done manually. It is decided to automate the transfer of the part between posts to respond to the level of production required, through an automated system that must be synchronized with the frequency of the press.

Tasks performed

The steps from the raw state of the part to the final geometry have been defined in 6 steps and an automated part handling system has been developed between these steps.

Mediante este proyecto se ha realizado la validación de la solución de automatización de un proceso de estampación, obteniendo las siguientes mejoras:

- Improvement of the competitiveness of the process, increasing the production cadence by 80%.

- Reduction of non-conformities of the product, considerably reducing the defects produced by the workers.

- Innovative and automated manufacturing process for the first time for the company.