- Duration: 2 months

- Year: 2017

- Participants: LEA ARTIBAI + C. Illunzar, S.L.

- Industry 4.0 and advanced manufacturing

Tasks performed

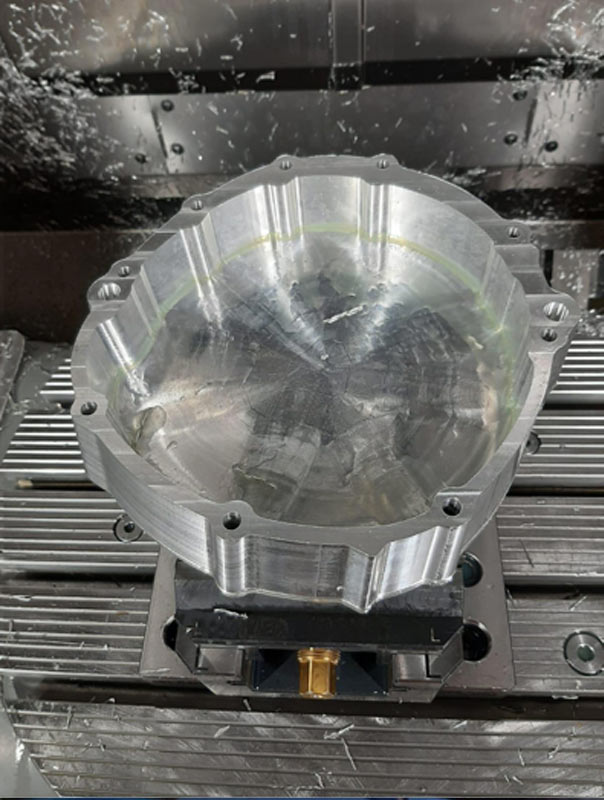

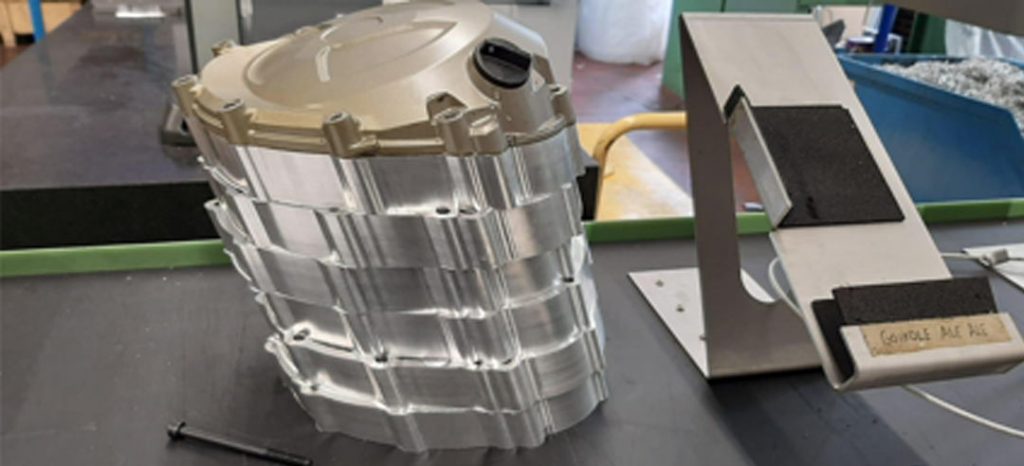

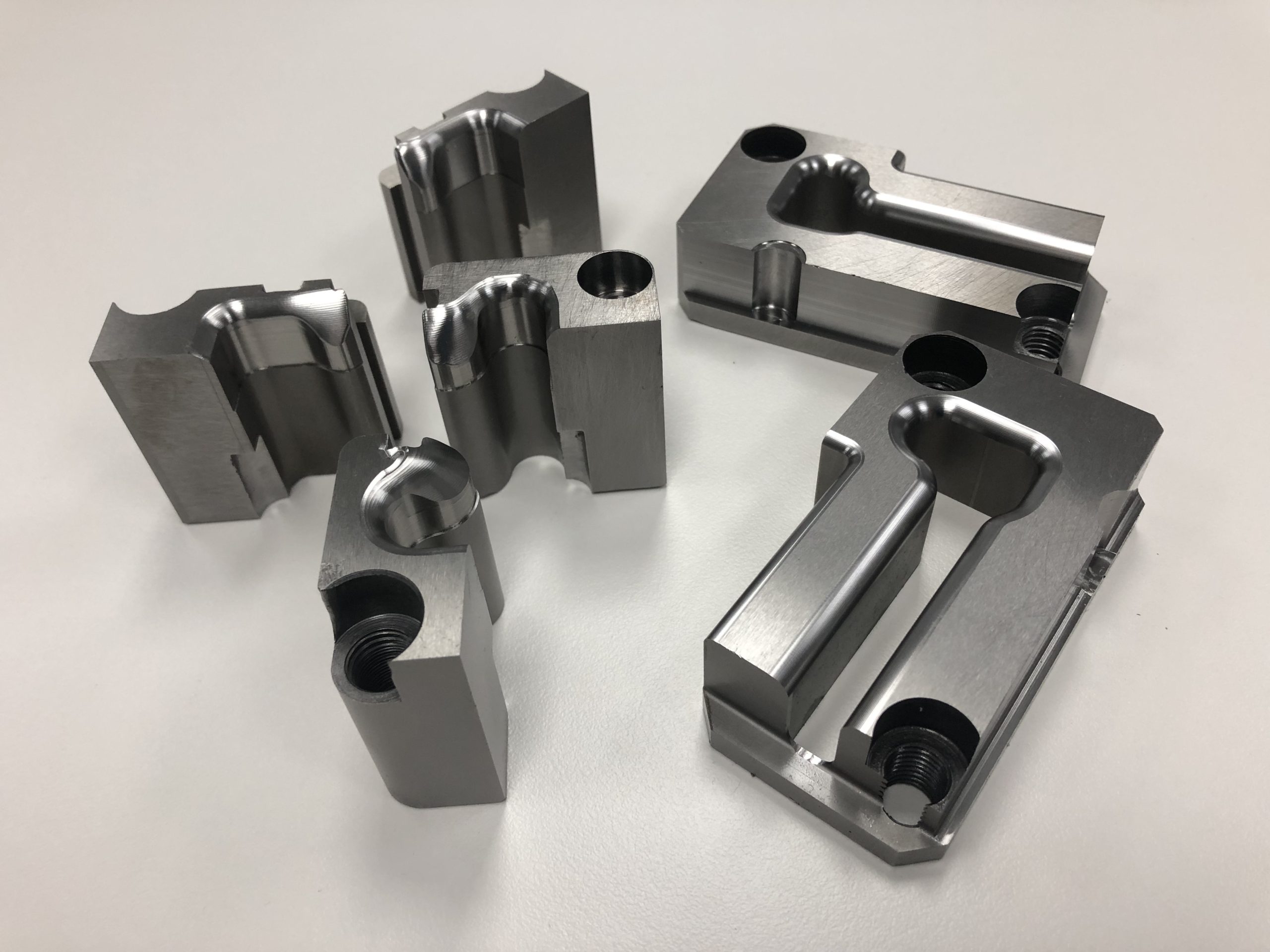

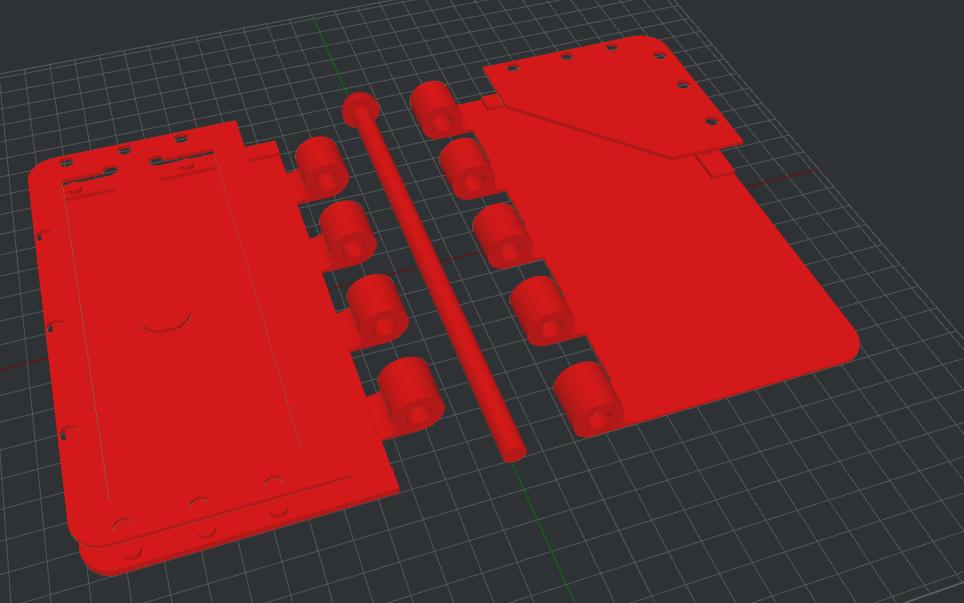

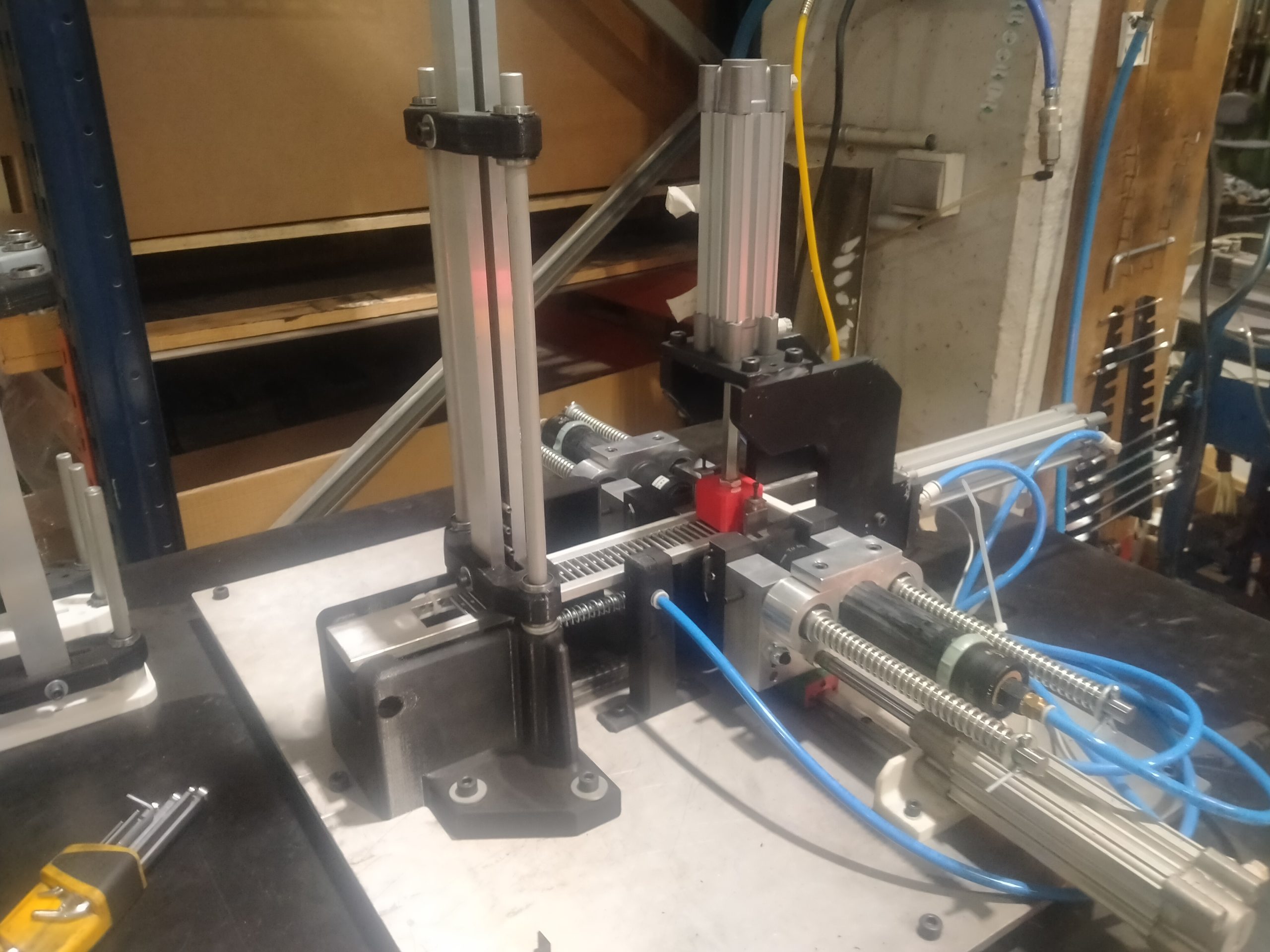

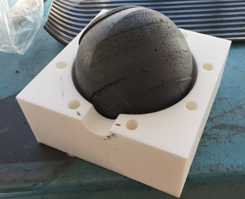

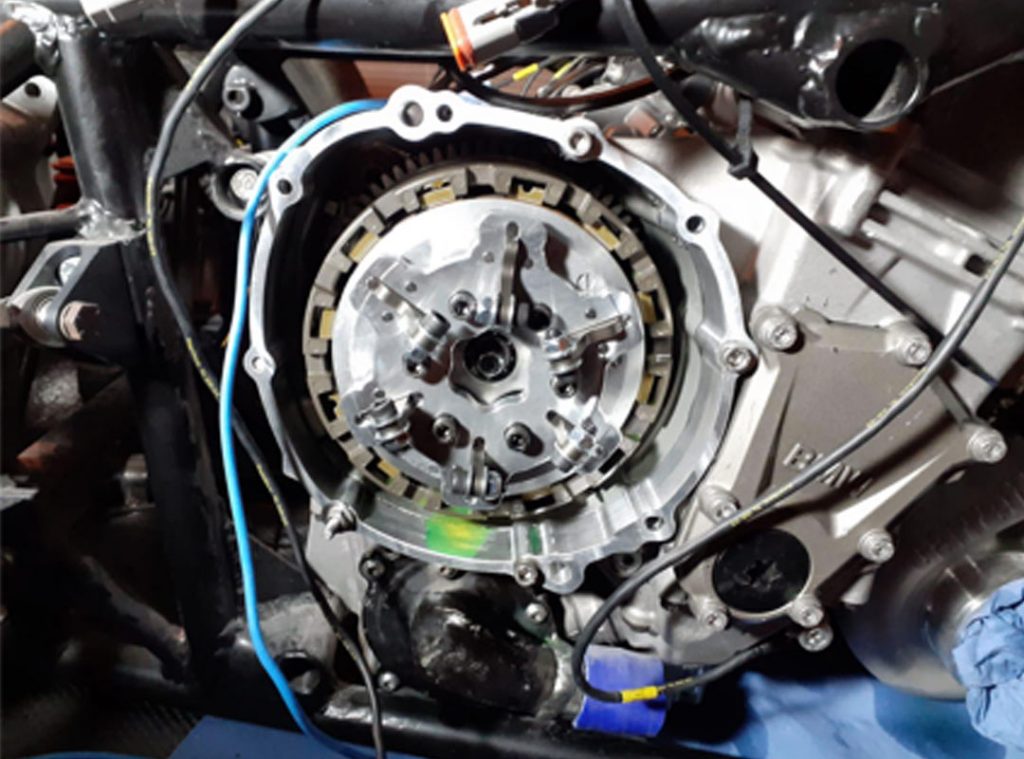

By means of the cloud point method in the coordinate measuring machine “Mitutoyo BHN-710” and taking as a model the clutch cover, the plane with which the 3D design of the separator will be executed is created. Subsequently, the machining program has been created using CAM software and 6 pieces of duralumin have been produced in the 5-axis machine “HERMLE C30-U” of the school plant.

Los separadores fabricados se han montado entre la carcasa del embrague del coche y la cubierta, aumentando el volumen.