- Duration: 9 months

- Year: 2019

- Participants: TOLOSALDEA LHI

- Industry 4.0 and advanced manufacturing

Project objectives

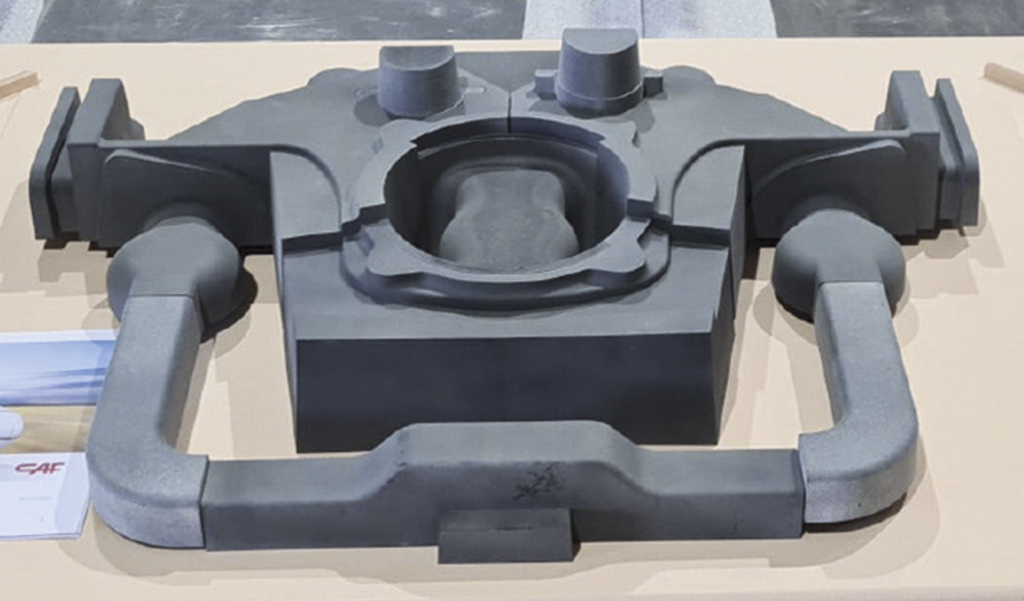

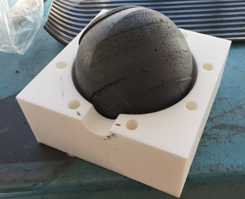

An important industrial dam of Tolosa, requested to TOLOSALDEA LHI, the realization of the following project with the ultimate aim of being able to develop and validate a solution by additive manufacturing to a model for foundry.

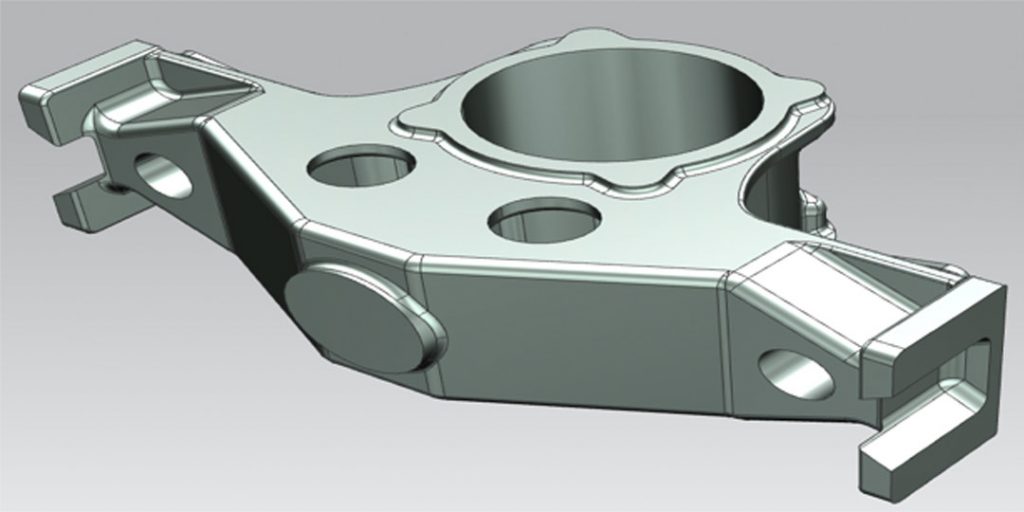

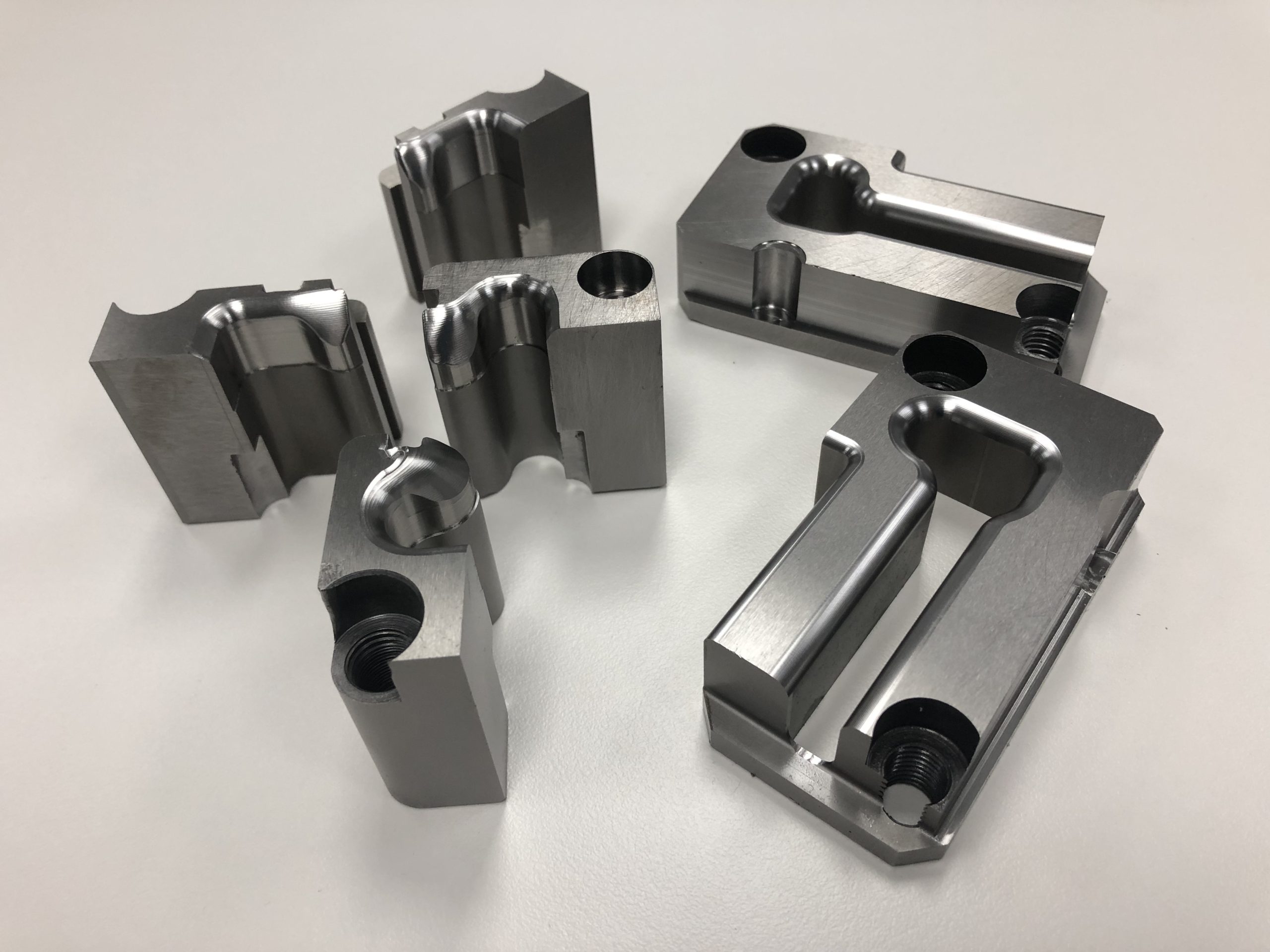

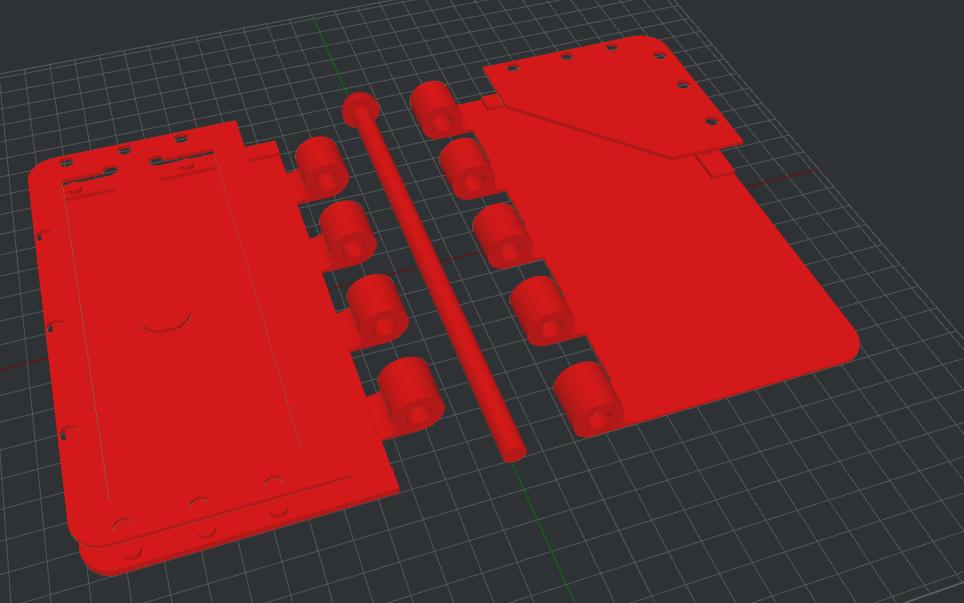

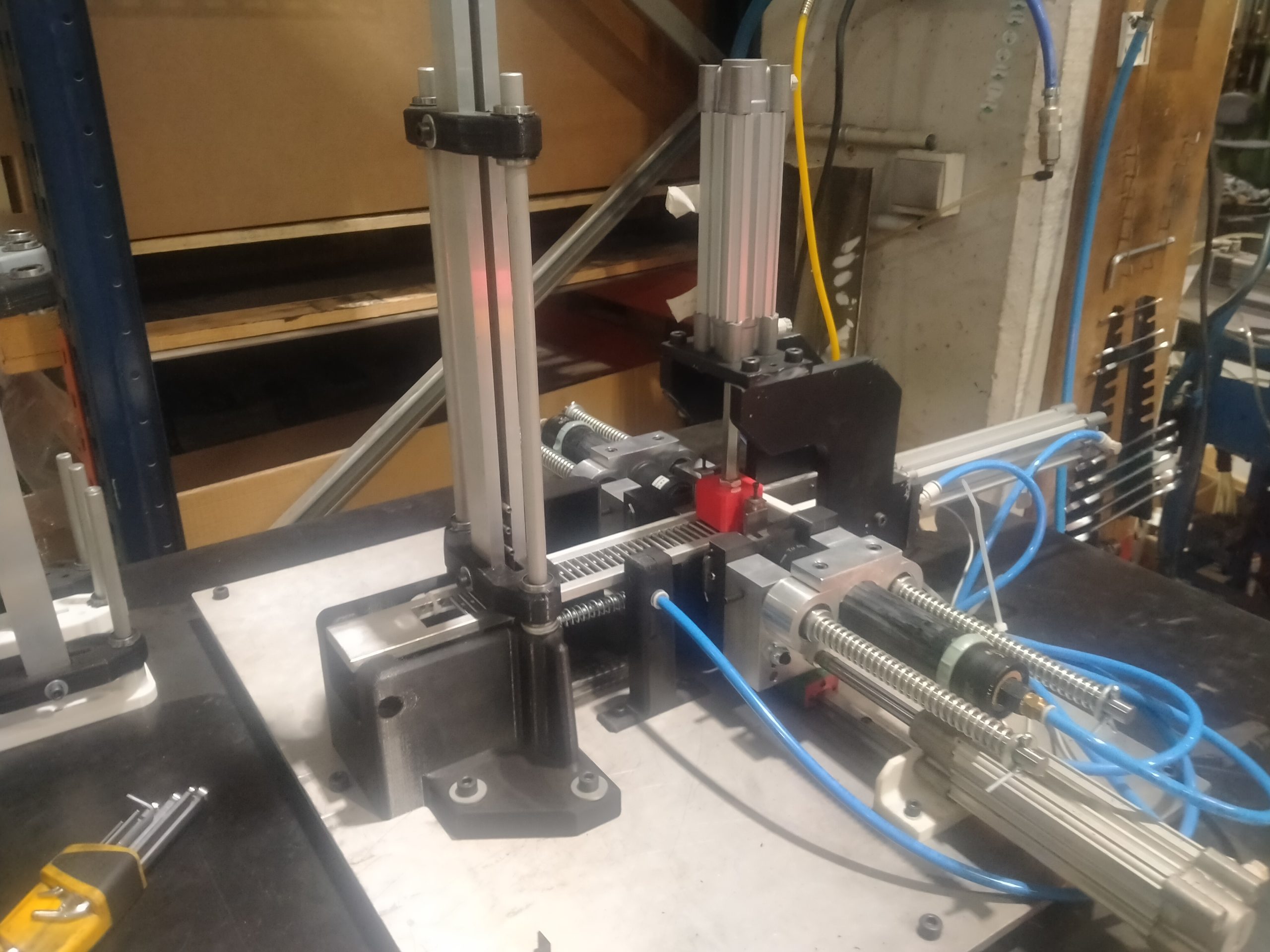

Over the course of a year, we have worked on the search for an alternative solution, based on additive manufacturing, for a model for casting steel parts, the design of it and the selection of the additive manufacturing technology that best suits the manufacture of the model.

At the same time, a search has been carried out for a supplier that could manufacture sand molds by additive manufacturing.

It should be noted that at this time the phases of search and identification of alternative technologies are concluded and also the phase of mold design and alternative model adapted to additive manufacturing.

In the 2020-2021 academic year, the manufacturing phase has begun in which the model will be manufactured using additive technology.

Tasks performed

- Preliminary definition of the current problems and sharing of available information.

- Definition of the scope of the project and technologies to be used, as well as validation of the budgets presented.

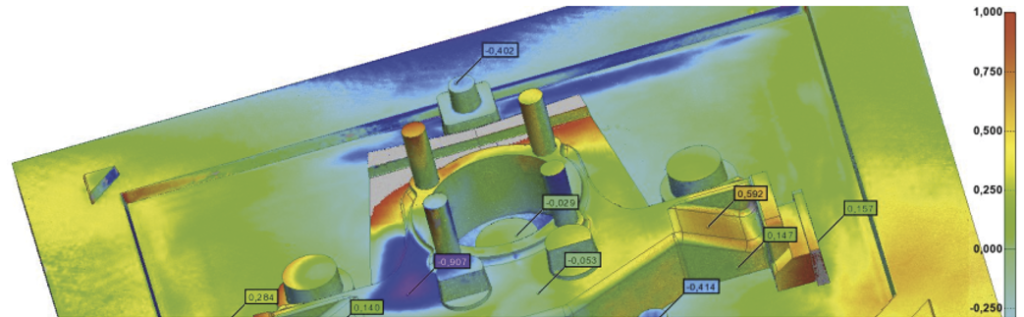

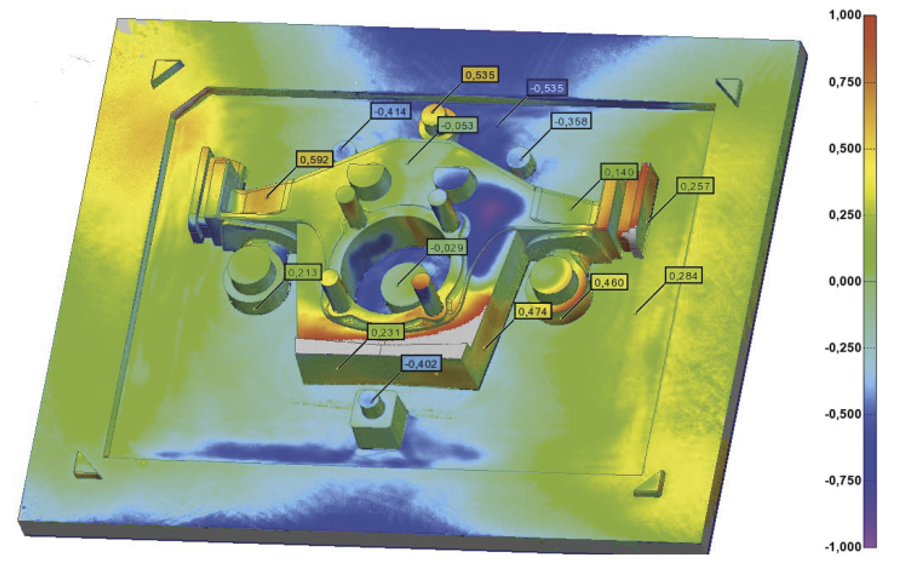

- Design and validation of the alternative model.

- Manufacture of alternative models using alternative technologies defined in the previous phases and validation of them.

- Manufacture of the parts using the alternative models and validation of the developed solution.